< Lifting systems Cranes and hydraulic lifters

Cranes and hydraulic lifts: essential tools for industry

In the world of machine shops and heavy industry, efficiency and safety are two fundamental pillars. Tools that enable heavy loads to be lifted and moved with precision and safety are indispensable to ensure smooth and trouble-free operations. Among these tools, cranes and hydraulic lifts occupy a prominent place, thanks to their versatility and reliability.

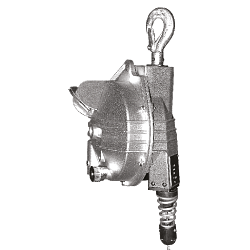

The technology behind hydraulic cranes and hoists

Hydraulic cranes and hoists are based on a simple but powerful physical principle: the transmission of force through an incompressible fluid. This principle, known as Pascal's law, allows the force applied to be multiplied, enabling very heavy loads to be lifted with relatively little effort. Hydraulic systems consist of cylinders, pumps, valves and reservoirs, which work in synergy to ensure smooth and controlled movement.

Practical applications in machine shops

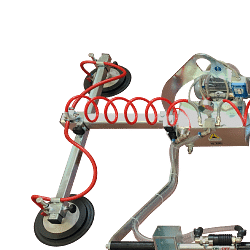

In machine shops, hydraulic cranes and hoists are used in a wide range of operations. From servicing heavy machinery to lifting components for assembly, these tools are essential for optimising production processes. Their ability to lift loads in tight spaces and operate with pinpoint accuracy makes them ideal for complex and dynamic work environments.

Benefits of using hydraulic cranes and hoists

The adoption of hydraulic cranes and hoists in machine shops offers numerous advantages. First of all, they improve workplace safety, reducing the risk of accidents related to manual lifting of heavy loads. They also increase operational efficiency, allowing lifting operations to be completed in a shorter time and with less physical effort. The versatility of these tools allows them to be adapted to different operational needs, making them a strategic investment for any workshop.

Maintenance and care of hydraulic systems

To ensure optimal performance and a long service life, regular maintenance of hydraulic systems is essential. This includes periodically checking oil levels, verifying the integrity of hoses and seals, and timely replacement of worn components. Proper maintenance not only prolongs the life of the cranes and lifts, but also ensures that they always operate safely.

Frequently asked questions about hydraulic lifts

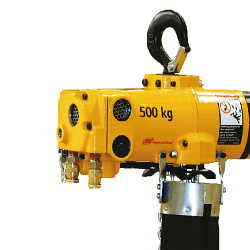

Many industry professionals ask questions about hydraulic lifts, trying to understand how to optimise their use. One of the most common questions concerns lifting capacity: how do you determine the maximum load a lift can handle? The answer depends on the technical specifications of the model in use, which must always be consulted before any operation. Another frequently asked question concerns compatibility with different types of loads: hydraulic lifts are designed to handle a wide range of weights and sizes, but it is essential to use the appropriate accessories to ensure safe lifting.

Innovations in the field of cranes and hydraulic lifts

The field of cranes and hydraulic lifts is constantly evolving, with innovations aimed at further improving efficiency and safety. Emerging trends include the integration of electronic control systems that enable more precise and automated management of lifting operations. In addition, the use of advanced materials and lightweight alloys is helping to reduce the overall weight of equipment, without compromising its strength and load capacity.

Conclusion: an investment for the future of the industry

In conclusion, cranes and hydraulic lifts are a key investment for machine shops and industry in general. Their ability to improve safety, increase efficiency and adapt to a wide range of applications makes them indispensable tools for meeting the challenges of the modern market. With proper maintenance and informed use, these tools will continue to play a crucial role in the industrial landscape, contributing to the success and growth of the companies that adopt them.

Read More Read Less