Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Lubricants for machine tools

- Home

- Lubricants for machine tools

- Powders and absorbents for oil

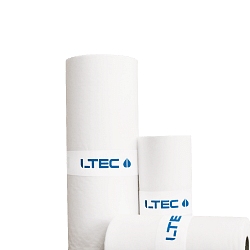

Powders and absorbents for oil

Oil absorbents and dusts: an in-depth analysis for machine shops

In the context of machine shops, oil and lubricant management is a crucial aspect of ensuring operational efficiency and environmental safety. Oil absorbents and oil dusts are indispensable tools to address the challenges of spillage and industrial fluid management. In this article, we will explore in detail what these products are, how they are used, the benefits they offer and answer frequently asked questions.

What are oil absorbents and oil powders?

Oil absorbents are materials designed to absorb and retain oils and other industrial liquids. These products are available in different forms, including cloths, rolls, cushions and barriers. Oil powders, on the other hand, are granular compounds that, when applied to a spill, quickly absorb the liquid, facilitating clean-up and removal.

Use of oil absorbents and oil powders in machine shops

In machine shops, oil spills can occur at any time, either during machine maintenance or due to unexpected breakdowns. Oil absorbents and oil powders are used to contain and clean up these spills quickly and efficiently. Absorbent wipes and rolls are ideal for small spills, while cushions and barriers are more suitable for handling larger volumes of liquids. Powders, due to their rapid absorption capacity, are particularly useful in emergency situations.

Advantages of using oil absorbents and powders

The adoption of oil absorbents and oil powders offers several advantages to machine shops. First of all, they improve safety at work by reducing the risk of slips and falls caused by oily surfaces. Furthermore, they help maintain a clean and tidy working environment, which is essential for operational efficiency. From an environmental point of view, these products help prevent soil and water contamination while complying with current hazardous waste management regulations.

Frequently asked questions about oil absorbents and oil powders

1. What is the difference between universal and oil-specific absorbents?

Universal absorbents are designed to absorb a wide range of liquids, including oils, water and chemicals. Oil-specific absorbents, on the other hand, are optimised to retain only oils and hydrocarbons, ensuring higher efficiency in these applications.

2. How are used oil absorbents and oil powders disposed of?

Absorbents and used oil powders must be disposed of according to local hazardous waste regulations. It is important to consult specific guidelines to ensure proper and safe disposal.

3. What are the criteria for choosing the right type of absorbent or oil powder?

Choosing the right type of absorbent or powder depends on several factors, including the type of liquid to be absorbed, the volume of the spillage and the application environment. It is advisable to assess the specific needs of the workshop in order to select the most suitable product.

Conclusions

Oil absorbents and oil powders are essential tools for machine shops, offering effective solutions for managing oil and lubricant spills. Their adoption not only improves safety and operational efficiency, but also contributes to environmental protection. Investing in these products means ensuring a safer and compliant working environment while protecting natural resources.

Read More Read LessIn the context of machine shops, oil and lubricant management is a crucial aspect of ensuring operational efficiency and environmental safety. Oil absorbents and oil dusts are indispensable tools to address the challenges of spillage and industrial fluid management. In this article, we will explore in detail what these products are, how they are used, the benefits they offer and answer frequently asked questions.

What are oil absorbents and oil powders?

Oil absorbents are materials designed to absorb and retain oils and other industrial liquids. These products are available in different forms, including cloths, rolls, cushions and barriers. Oil powders, on the other hand, are granular compounds that, when applied to a spill, quickly absorb the liquid, facilitating clean-up and removal.

Use of oil absorbents and oil powders in machine shops

In machine shops, oil spills can occur at any time, either during machine maintenance or due to unexpected breakdowns. Oil absorbents and oil powders are used to contain and clean up these spills quickly and efficiently. Absorbent wipes and rolls are ideal for small spills, while cushions and barriers are more suitable for handling larger volumes of liquids. Powders, due to their rapid absorption capacity, are particularly useful in emergency situations.

Advantages of using oil absorbents and powders

The adoption of oil absorbents and oil powders offers several advantages to machine shops. First of all, they improve safety at work by reducing the risk of slips and falls caused by oily surfaces. Furthermore, they help maintain a clean and tidy working environment, which is essential for operational efficiency. From an environmental point of view, these products help prevent soil and water contamination while complying with current hazardous waste management regulations.

Frequently asked questions about oil absorbents and oil powders

1. What is the difference between universal and oil-specific absorbents?

Universal absorbents are designed to absorb a wide range of liquids, including oils, water and chemicals. Oil-specific absorbents, on the other hand, are optimised to retain only oils and hydrocarbons, ensuring higher efficiency in these applications.

2. How are used oil absorbents and oil powders disposed of?

Absorbents and used oil powders must be disposed of according to local hazardous waste regulations. It is important to consult specific guidelines to ensure proper and safe disposal.

3. What are the criteria for choosing the right type of absorbent or oil powder?

Choosing the right type of absorbent or powder depends on several factors, including the type of liquid to be absorbed, the volume of the spillage and the application environment. It is advisable to assess the specific needs of the workshop in order to select the most suitable product.

Conclusions

Oil absorbents and oil powders are essential tools for machine shops, offering effective solutions for managing oil and lubricant spills. Their adoption not only improves safety and operational efficiency, but also contributes to environmental protection. Investing in these products means ensuring a safer and compliant working environment while protecting natural resources.