< Lubricants for machine tools Minimal lubrication systems

CNC minimalist lubrication systems: innovation and precision for machine shops

In the world of machine shops, efficiency and precision are key elements in ensuring end-product quality and market competitiveness. CNC minimalist lubrication systems represent an advanced solution that meets these requirements, offering numerous advantages over traditional lubrication methods. In this in-depth look, we will explore in detail what CNC minimalist lubrication systems are, how they work, the benefits they bring and answers to frequently asked questions on this topic.

What are CNC minimal lubrication systems?

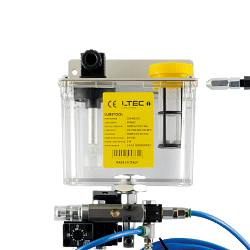

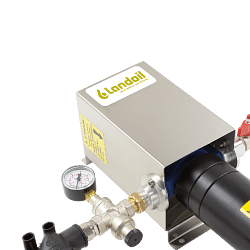

CNC minimal lubrication systems are devices designed to deliver a precise and controlled amount of lubricant directly to the work surface during machining operations. Unlike traditional methods that use large amounts of oil or emulsions, these systems use a minimal amount of lubricant, often in the form of micro-droplets, to reduce friction and heat generated during the cutting or milling process.

How do CNC minimal lubrication systems work?

The operating principle of CNC minimal lubrication systems is based on the delivery of a mixture of compressed air and lubricant through specially designed nozzles. This mixture is sprayed directly onto the tool and work surface, creating a thin film that reduces friction and heat. The precise application of the lubricant is ensured by an electronic control that adjusts the flow to the specific requirements of the machining process.

Advantages of CNC minimalist lubrication systems

The adoption of CNC minimal lubrication systems offers numerous advantages over traditional methods. Some of the main benefits include:

1. Reduced operating costs: The use of a minimal amount of lubricant results in a significant reduction in costs associated with the purchase and disposal of oils. In addition, the lower quantity of oily residue simplifies machine cleaning and maintenance.

2. Improved product quality: Precise and controlled lubrication reduces tool wear and improves the surface finish of machined parts, ensuring a higher quality of the end product.

3. Increased tool life: Reducing friction and heat during cutting operations prolongs tool life, reducing replacement frequency and associated costs.

4. Reduced environmental impact: The use of minimal amounts of lubricant helps reduce the environmental impact of machining operations, limiting the production of oily waste and improving the overall sustainability of the production process.

5. Improved work safety: Reducing oil mist and slippery residues on the shop floor improves safety conditions for operators, reducing the risk of accidents.

Applications of CNC minimum quantity lubrication systems

CNC minimal lubrication systems find application in a wide range of machining processes, including milling, turning, drilling and grinding. They are particularly suitable for high-speed machining and difficult-to-machine materials, such as titanium alloys and stainless steels, where heat and friction management is crucial for optimal results.

Frequently asked questions about CNC minimum quantity lubrication systems

1. What types of lubricants are used in CNC minimal lubrication systems?

Lubricants used in CNC minimal lubrication systems are generally synthetic or vegetable oils, formulated for high lubrication efficiency and low volatility. The choice of lubricant depends on the specific requirements of the machining process and the material to be machined.

2. Can CNC minimum quantity lubrication systems be integrated into existing machines?

Yes, many CNC minimal lubrication systems are designed to be easily integrated on existing machine tools, without the need for significant modifications. However, it is important to consult the system manufacturer to ensure compatibility and correct installation.

3. What are the maintenance requirements for CNC minimal lubrication systems?

CNC minimal lubrication systems require regular maintenance to ensure optimal performance. This includes cleaning the nozzles, checking that the control valves are working properly, and periodically replacing the air and lubricant filters.

4. Are CNC minimal lubrication systems suitable for all machining operations?

Although CNC minimal lubrication systems are suitable for many machining operations, they may not be ideal for processes that require intensive cooling or for materials that generate high amounts of heat. In such cases, complementary cooling systems should be considered.

5. What are the economic considerations in adopting minimal CNC lubrication systems?

The adoption of CNC minimal lubrication systems involves an initial investment in the purchase and installation of the system. However, operating cost savings, reduced downtime and increased end-product quality can quickly offset the initial investment, making these systems a cost-effective choice for many machine shops.

In conclusion, CNC minimalist lubrication systems represent an innovative and sustainable solution for machine shops wishing to improve efficiency, reduce costs and increase end-product quality. With proper implementation and maintenance, these systems can offer significant benefits and contribute to the long-term success of machining operations.

Read More Read Less