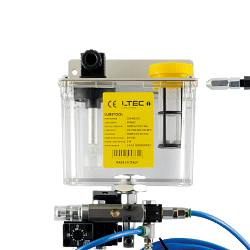

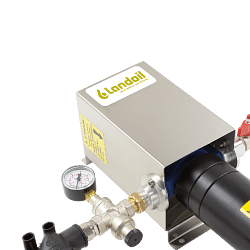

< Lubricants for machine tools Aspirators for oil mist

Oil mist aspirators are an essential component for modern machine shops, where air quality and workplace safety are paramount. These devices are designed to remove airborne oil particles generated during machining processes such as turning, milling and grinding. The accumulation of oil mists not only compromises air quality, but can also pose a health risk to operators and adversely affect machine efficiency.

Understanding how oil mist extractors work

Oil mist aspirators operate through a filtration process that captures and separates oil particles from the air. These systems use a combination of mechanical and coalescing filters to ensure effective mist removal. Mechanical filters trap larger particles, while coalescing filters aggregate the smaller particles into larger droplets, which can be easily collected and disposed of. Some advanced models also include HEPA filters to capture ultra-fine particles, ensuring even cleaner air.

The importance of vacuum cleaners for health and safety

Prolonged exposure to oily mists can cause respiratory problems, skin irritation and other health disorders. In addition, the slippery surfaces created by oil accumulation can increase the risk of accidents at work. Oil mist aspirators significantly reduce these risks, improving air quality and creating a safer working environment. This not only protects the health of operators, but also helps reduce the costs associated with occupational illnesses and accidents.

Economic and operational benefits of oil mist extractors

In addition to health and safety benefits, the installation of oil mist aspirators can lead to significant economic and operational advantages. The reduction of oil particles in the air helps keep machines cleaner and operational for longer, reducing the need for maintenance and repairs. In addition, a cleaner working environment can improve operator productivity, reducing downtime and increasing overall workshop efficiency.

Selection and installation of oil mist vacuum cleaners

Choosing the right vacuum cleaner depends on several factors, including the type of machining operation, the volume of mist generated, and the size of the workshop. It is important to assess the suction capacity, filtration efficiency and ease of maintenance of the device. Installation must be performed by qualified professionals to ensure optimal operation and compliance with safety regulations. In addition, it is essential to schedule regular maintenance to ensure that the filters are clean and functioning properly.

Frequently asked questions about oil mist vacuum cleaners

1. What is the average lifetime of filters in oil mist aspirators?

The service life of filters depends on the intensity of use and the type of processing. In general, mechanical filters can last between six months and one year, whereas coalescing filters may require more frequent replacement.

2. Are oil mist extractors noisy?

Most modern vacuum cleaners are designed to operate at low noise levels, but it is always advisable to check the specifications of the model to ensure that it meets the needs of the working environment.

3. Can the oil collected by vacuum cleaners be recycled?

Yes, many vacuum cleaner systems allow you to collect and recycle oil, reducing waste and contributing to a more sustainable approach.

4. Do oil mist extractors require external ventilation?

Not necessarily. Many models are designed to operate indoors without the need for external ventilation, but it is important to follow the manufacturer's guidelines.

5. What are the safety regulations for Oil mist aspirators?

Regulations may vary by country and industry, but in general, vacuum cleaners must comply with occupational health and safety standards, such as those set by OSHA or the EU.

Conclusion

Oil mist aspirators are indispensable tools for machine shops that want to ensure a safe, clean and efficient working environment. Investing in a quality vacuum cleaner system not only protects the health of operators, but also offers significant economic and operational benefits. With proper selection, installation and maintenance, oil mist extractors can help improve the productivity and sustainability of mechanical operations.

Read More Read Less