Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Furnishings and storage

- Home

- Furnishings and storage

- Scrap holders

Scrap holders

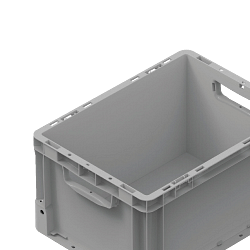

Industrial scrap buckets are an essential element in the landscape of machine shops and industries dealing with heavy processing. These tools, designed for handling and transporting waste materials, are essential to ensure efficiency and safety in production processes. In this in-depth look, we will explore in detail what industrial scrap buckets are, what they are used for, how they are used, the advantages they offer and answer the most frequently asked questions on this topic.

What are industrial bucket crushers

Industrial scrap buckets are equipment designed for the collection, transport and disposal of waste materials and scrap metal. These buckets are made of strong and durable materials, such as steel, to withstand heavy loads and harsh working conditions. Their structure is designed for easy loading and unloading of materials, often equipped with automatic or manual tipping mechanisms.

Use of grab buckets in machine shops

In machine shops, scrap buckets are used to handle machining residues such as metal shavings, cutting waste and other waste materials. These tools keep the work area clean and organised, reducing the risk of accidents and improving operational efficiency. The buckets can be easily moved with forklifts or cranes, enabling quick and safe transport of materials to disposal or recycling areas.

Benefits of industrial bucket trucks

There are several advantages to using industrial bucket trucks. First of all, they improve work safety by reducing the risk of accidents related to manual handling of heavy materials. In addition, they help optimise production processes, allowing more efficient waste management and reduced downtime. Grab buckets are also a long-term investment, thanks to their robustness and durability, which guarantee prolonged use without the need for frequent replacement.

How to choose the right bucket carrier

The choice of the right grab bucket depends on several factors, including the type of material to be handled, the required loading capacity and the specific operational needs of the company. It is also important to consider the size and design of the bucket to ensure that it is compatible with the available lifting equipment. It is also advisable to opt for models with advanced safety systems, such as safety locks and controlled tipping mechanisms, to ensure safe and efficient use.

Bucket maintenance and care

To ensure optimal operation and prolong the life of your bucket trucks, regular maintenance is essential. This includes periodic cleaning to remove material residue, inspection of moving parts for signs of wear or damage, and lubrication of tipping mechanisms. In addition, it is important to follow the manufacturer's instructions regarding use and maintenance to avoid operational problems and ensure operator safety.

Frequently asked questions about industrial skip loaders

1. What is the typical loading capacity of a clamshell bucket?

The loading capacity of the grab buckets varies depending on the model and manufacturer, but can generally range from a few hundred kilograms to several tonnes. It is important to choose a bucket with a capacity suited to the specific needs of the company.

2. Can scrap buckets be used for non-metallic materials?

Although designed primarily for scrap metal, many scrap metal buckets can also be used for other types of scrap materials, such as plastic or wood, as long as the loading capacity and specifications are met.

3. What are the safety regulations to be followed when using the grapple buckets?

The use of grapple buckets must comply with current safety regulations, which may vary depending on the country and industry sector. It is essential that operators are properly trained and that equipment is regularly inspected and maintained.

4. Is it possible to customise grab buckets for specific needs?

Many manufacturers offer the possibility to customise their bucket trucks to meet specific needs, such as special dimensions, customised tipping mechanisms or special materials to withstand extreme environmental conditions.

5. What are the alternatives to bucket trucks for industrial waste management?

In addition to scrap buckets, there are other solutions for industrial waste management, such as containers, compactors and pneumatic transport systems. The choice of the most suitable alternative depends on the specific operational requirements and the type of materials to be handled.

In conclusion, industrial waste buckets are indispensable tools for machine shops and industries that need to handle large quantities of waste materials. Their robustness, efficiency and versatility make them an ideal choice for improving safety and operational efficiency. With proper maintenance and use, scrap buckets can provide reliable and long-lasting service, contributing to the overall success of industrial operations.

Read More Read LessWhat are industrial bucket crushers

Industrial scrap buckets are equipment designed for the collection, transport and disposal of waste materials and scrap metal. These buckets are made of strong and durable materials, such as steel, to withstand heavy loads and harsh working conditions. Their structure is designed for easy loading and unloading of materials, often equipped with automatic or manual tipping mechanisms.

Use of grab buckets in machine shops

In machine shops, scrap buckets are used to handle machining residues such as metal shavings, cutting waste and other waste materials. These tools keep the work area clean and organised, reducing the risk of accidents and improving operational efficiency. The buckets can be easily moved with forklifts or cranes, enabling quick and safe transport of materials to disposal or recycling areas.

Benefits of industrial bucket trucks

There are several advantages to using industrial bucket trucks. First of all, they improve work safety by reducing the risk of accidents related to manual handling of heavy materials. In addition, they help optimise production processes, allowing more efficient waste management and reduced downtime. Grab buckets are also a long-term investment, thanks to their robustness and durability, which guarantee prolonged use without the need for frequent replacement.

How to choose the right bucket carrier

The choice of the right grab bucket depends on several factors, including the type of material to be handled, the required loading capacity and the specific operational needs of the company. It is also important to consider the size and design of the bucket to ensure that it is compatible with the available lifting equipment. It is also advisable to opt for models with advanced safety systems, such as safety locks and controlled tipping mechanisms, to ensure safe and efficient use.

Bucket maintenance and care

To ensure optimal operation and prolong the life of your bucket trucks, regular maintenance is essential. This includes periodic cleaning to remove material residue, inspection of moving parts for signs of wear or damage, and lubrication of tipping mechanisms. In addition, it is important to follow the manufacturer's instructions regarding use and maintenance to avoid operational problems and ensure operator safety.

Frequently asked questions about industrial skip loaders

1. What is the typical loading capacity of a clamshell bucket?

The loading capacity of the grab buckets varies depending on the model and manufacturer, but can generally range from a few hundred kilograms to several tonnes. It is important to choose a bucket with a capacity suited to the specific needs of the company.

2. Can scrap buckets be used for non-metallic materials?

Although designed primarily for scrap metal, many scrap metal buckets can also be used for other types of scrap materials, such as plastic or wood, as long as the loading capacity and specifications are met.

3. What are the safety regulations to be followed when using the grapple buckets?

The use of grapple buckets must comply with current safety regulations, which may vary depending on the country and industry sector. It is essential that operators are properly trained and that equipment is regularly inspected and maintained.

4. Is it possible to customise grab buckets for specific needs?

Many manufacturers offer the possibility to customise their bucket trucks to meet specific needs, such as special dimensions, customised tipping mechanisms or special materials to withstand extreme environmental conditions.

5. What are the alternatives to bucket trucks for industrial waste management?

In addition to scrap buckets, there are other solutions for industrial waste management, such as containers, compactors and pneumatic transport systems. The choice of the most suitable alternative depends on the specific operational requirements and the type of materials to be handled.

In conclusion, industrial waste buckets are indispensable tools for machine shops and industries that need to handle large quantities of waste materials. Their robustness, efficiency and versatility make them an ideal choice for improving safety and operational efficiency. With proper maintenance and use, scrap buckets can provide reliable and long-lasting service, contributing to the overall success of industrial operations.