< Workshop equipment Threaded inserts

Professional thread inserts are an essential and innovative solution in the machine shop sector, making a significant contribution to the maintenance and repair of threaded components. These devices, also known as thread inserts, are designed to restore damaged or worn threads, improving the strength and durability of mechanical components. In this in-depth review, we will explore in detail what professional thread inserts are, how they are used, the benefits they offer and answer frequently asked questions on this topic.

Understanding professional thread inserts

Professional thread inserts are cylindrical inserts that are inserted into threaded holes to restore or improve the original thread. They are made of durable materials such as stainless steel, bronze or titanium, depending on the specific requirements of the application. These inserts are particularly useful in situations where the original thread has been damaged due to wear, corrosion or overloading.

Applications and use of thread inserts

The applications of professional thread inserts are many and span various industries, including automotive, aerospace, machine manufacturing and electronics. In a machine shop context, these inserts are used to repair damaged threads on components such as engine blocks, cylinder heads, crankcases and other critical parts. Installing a thread insert requires precision and expertise, as the original hole must be properly prepared to accommodate the insert.

Advantages of professional thread inserts

The use of professional thread inserts offers several advantages. First of all, they restore the functionality of otherwise compromised components, avoiding the need to replace entire parts, thus saving time and costs. In addition, thread inserts improve thread strength, reducing the risk of future damage. This is especially important in high-stress applications, where safety and reliability are paramount.

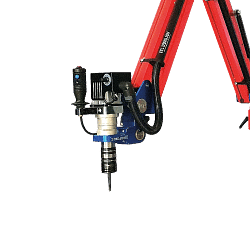

Installation process of thread inserts

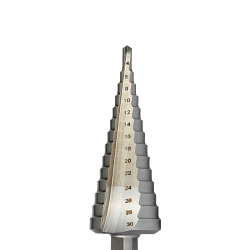

The installation of a professional thread lead requires a number of precise steps. First, the damaged hole must be enlarged and rethreaded to accommodate the insert. Next, the insert is screwed into the prepared hole using a special installation tool. Once correctly positioned, the insert provides a new internal thread ready for use. It is essential to follow the manufacturer's specifications to ensure correct and durable installation.

Materials and design of thread inserts

Professional thread inserts are available in a variety of materials and designs to meet different application needs. Stainless steel is commonly used for its corrosion resistance and durability. In applications requiring light weight, such as aerospace, titanium inserts can be used. Insert designs can vary, with options including helical threads, spiral threads and self-tapping inserts, each with specific characteristics to optimise performance.

Frequently asked questions about professional thread inserts

1. What are the standard sizes of thread inserts?

The dimensions of thread inserts vary depending on the manufacturer and application. It is important to select the correct insert according to the specifications of the component to be repaired.

2. Can thread inserts be used on different materials?

Yes, thread inserts can be used on a variety of materials, including metals and alloys. However, it is essential to choose the insert material based on the material properties of the original component.

3. How long does it take to install a thread insert?

The installation time depends on the complexity of the component and the experience of the operator. In general, installation can be completed in a few minutes with the right tools.

4. Can thread inserts be removed and replaced?

Yes, in many cases thread inserts can be removed and replaced if necessary. However, it is important to follow the manufacturer's instructions to avoid damage to the component.

5. What are the safety considerations during installation?

During installation, it is essential to wear personal protective equipment and follow safety guidelines to avoid injury. In addition, it is important to use quality tools to ensure safe and accurate installation.

Conclusion

Professional thread inserts are an indispensable resource for machine shops and other industries, offering an effective solution for repairing and improving damaged threads. Due to their versatility, durability and ease of installation, these inserts are a valuable investment in ensuring the longevity and reliability of mechanical components. With a thorough understanding of their applications and benefits, workshops can optimise their operations and reduce maintenance costs while maintaining high standards of quality and safety.

Read More Read Less