Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Workshop equipment

- Home

- Workshop equipment

- Tapered cutters for sheet metal

Tapered cutters for sheet metal

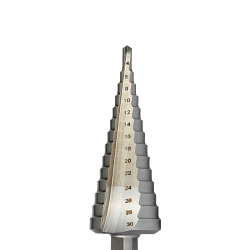

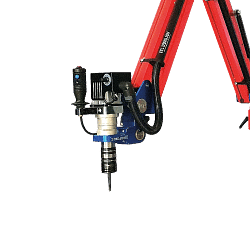

Conical sheet metal cutters are an essential part of the machining landscape, especially when it comes to operations requiring precision and reliability. These tools, designed to perform conical cuts on metal surfaces, are essential for a wide range of industrial applications, from metal construction to the production of automotive components.

Introduction to conical sheet metal cutters

Conical sheet metal cutters are cutting tools used primarily to create conical holes in metal surfaces. These tools are characterised by a conical geometry that allows holes to be made at a specific angle, guaranteeing perfect adaptability for applications requiring precision and a high quality finish. Their design is studied to minimise vibration and improve stability during the cutting process, thus ensuring optimal results.

Conical milling cutter applications

Conical milling cutters are used in numerous industrial sectors. In machine shops, they are used to create conical holes that facilitate the assembly of metal components. In the automotive industry, these milling cutters are used for the production of parts requiring tight tolerances and high-quality surface finishes. Furthermore, in the aeronautical field, conical milling cutters are essential for machining structural components that must withstand high stresses.

Advantages of conical milling cutters

The use of conical sheet metal cutters offers numerous advantages. Firstly, their ability to produce conical holes with millimetre precision reduces the need for further machining, saving time and resources. Furthermore, due to their geometry, these cutters ensure an even distribution of cutting forces, minimising tool wear and extending tool life. Another significant advantage is the reduction of vibration during the cutting process, which results in greater stability and a superior surface finish.

Correct use of conical sheet metal cutters

To achieve the best results, it is essential to use conical sheet metal cutters correctly. Before starting the cutting process, it is important to select the conical cutter with the appropriate angle and diameter for the specific application. In addition, it is essential to set the cutting speed and feed rate according to the sheet material and tool specifications. Proper lubrication during the cutting process is crucial to reduce friction and prevent the tool from overheating.

Frequently asked questions about conical sheet metal cutters

1. What materials can be machined with conical sheet metal cutters?

Conical sheet metal cutters are suitable for processing a wide range of metal materials, including steel, aluminium, copper and special alloys. It is important to select the right tool according to the material to be processed to ensure optimal results.

2. How do I choose the right conical cutter for a specific application?

The choice of taper cutter depends on several factors, including the type of material to be machined, the angle of the hole required and the diameter of the hole. It is advisable to consult the manufacturer's technical specifications to select the most suitable tool.

3. What are the best practices for the maintenance of conical sheet metal cutters?

To ensure the long life of conical cutters, it is important to clean them thoroughly after each use to remove material residues. It is also advisable to inspect the tool regularly for signs of wear and replace it if necessary.

Conclusions

Conical sheet metal cutters are indispensable tools for machine shops and many industries. Their ability to produce conical holes with precision and reliability makes them an ideal choice for applications requiring tight tolerances and high quality finishes. By using these cutters correctly and following best maintenance practices, tool efficiency and tool life can be maximised, ensuring excellent results in every machining operation.

Read More Read LessIntroduction to conical sheet metal cutters

Conical sheet metal cutters are cutting tools used primarily to create conical holes in metal surfaces. These tools are characterised by a conical geometry that allows holes to be made at a specific angle, guaranteeing perfect adaptability for applications requiring precision and a high quality finish. Their design is studied to minimise vibration and improve stability during the cutting process, thus ensuring optimal results.

Conical milling cutter applications

Conical milling cutters are used in numerous industrial sectors. In machine shops, they are used to create conical holes that facilitate the assembly of metal components. In the automotive industry, these milling cutters are used for the production of parts requiring tight tolerances and high-quality surface finishes. Furthermore, in the aeronautical field, conical milling cutters are essential for machining structural components that must withstand high stresses.

Advantages of conical milling cutters

The use of conical sheet metal cutters offers numerous advantages. Firstly, their ability to produce conical holes with millimetre precision reduces the need for further machining, saving time and resources. Furthermore, due to their geometry, these cutters ensure an even distribution of cutting forces, minimising tool wear and extending tool life. Another significant advantage is the reduction of vibration during the cutting process, which results in greater stability and a superior surface finish.

Correct use of conical sheet metal cutters

To achieve the best results, it is essential to use conical sheet metal cutters correctly. Before starting the cutting process, it is important to select the conical cutter with the appropriate angle and diameter for the specific application. In addition, it is essential to set the cutting speed and feed rate according to the sheet material and tool specifications. Proper lubrication during the cutting process is crucial to reduce friction and prevent the tool from overheating.

Frequently asked questions about conical sheet metal cutters

1. What materials can be machined with conical sheet metal cutters?

Conical sheet metal cutters are suitable for processing a wide range of metal materials, including steel, aluminium, copper and special alloys. It is important to select the right tool according to the material to be processed to ensure optimal results.

2. How do I choose the right conical cutter for a specific application?

The choice of taper cutter depends on several factors, including the type of material to be machined, the angle of the hole required and the diameter of the hole. It is advisable to consult the manufacturer's technical specifications to select the most suitable tool.

3. What are the best practices for the maintenance of conical sheet metal cutters?

To ensure the long life of conical cutters, it is important to clean them thoroughly after each use to remove material residues. It is also advisable to inspect the tool regularly for signs of wear and replace it if necessary.

Conclusions

Conical sheet metal cutters are indispensable tools for machine shops and many industries. Their ability to produce conical holes with precision and reliability makes them an ideal choice for applications requiring tight tolerances and high quality finishes. By using these cutters correctly and following best maintenance practices, tool efficiency and tool life can be maximised, ensuring excellent results in every machining operation.