< Workshop equipment Industrial aspirators

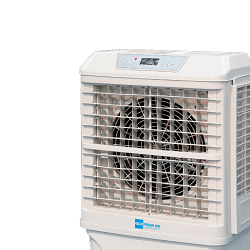

Professional industrial vacuum cleaners are a crucial element for modern machine shops, where air quality management and clean working environments are crucial to ensure safety and operational efficiency. These devices are designed to address the unique challenges posed by industrial environments characterised by dust, fumes and particles that can compromise worker health and product quality.

The importance of industrial vacuum cleaners in machine shops

Mechanical workshops are complex environments where numerous activities that generate dust and fumes take place. Metalworking, welding and other similar operations produce particles that, if not properly managed, can accumulate in the air and pose a health risk. Professional industrial vacuum cleaners are designed to meet these challenges, ensuring a safer and cleaner working environment.

How industrial vacuum cleaners work

Industrial vacuum cleaners operate through a vacuum system that captures airborne particles. These devices are equipped with powerful motors and advanced filtration systems that retain even the finest particles. HEPA filters, for example, are able to capture microscopic-sized particles, ensuring cleaner and safer air.

Advantages of using professional industrial vacuum cleaners

The adoption of professional industrial vacuum cleaners offers numerous advantages. First of all, they improve air quality, reducing the risk of respiratory diseases among workers. In addition, they help keep machinery and surfaces clean, reducing wear and tear and prolonging equipment life. A clean and safe working environment also increases productivity, as workers can better concentrate on their tasks without worrying about air quality.

Types of industrial vacuum cleaners

There are different types of industrial vacuum cleaners, each designed for specific needs. Dry vacuum cleaners are ideal for removing dust and solid particles, while wet vacuums are designed to handle liquids and wet materials. Some models combine both functionalities, offering greater versatility. In addition, centralised vacuum cleaners are an effective solution for large workshops, as they allow air quality to be managed in several areas at the same time.

Considerations when choosing an industrial vacuum cleaner

When choosing an industrial vacuum cleaner, it is important to consider several factors. Motor power, tank capacity and filter type are key elements to evaluate. In addition, it is essential to consider the specific needs of the workshop, such as the type of materials processed and the size of the area to be covered. A careful analysis of these factors will help you select the most suitable device for your needs.

Maintenance and care of industrial vacuum cleaners

To ensure optimal operation and prolong the life of industrial vacuum cleaners, regular maintenance is essential. This includes periodic cleaning and replacement of filters, checking seals, and verifying the proper functioning of the motor. A well-structured maintenance programme not only improves the efficiency of the device, but also reduces long-term operating costs.

Frequently asked questions about industrial vacuum cleaners

1. What is the difference between an industrial vacuum cleaner and a domestic vacuum cleaner?

Industrial vacuum cleaners are designed to handle larger volumes of dust and particles than domestic models. They are equipped with more powerful motors and advanced filtration systems to ensure superior performance in industrial environments.

2. How often should filters in industrial vacuum cleaners be changed?

The frequency of filter replacement depends on the use and type of particles handled. In general, it is advisable to check the filters monthly and replace them when necessary to maintain the efficiency of the device.

3. Can industrial vacuum cleaners be used to remove welding fumes?

Yes, many industrial vacuum cleaners are designed to capture welding fumes and other airborne particles, helping to improve air quality in machine shops.

4. What are the costs associated with the use of industrial vacuum cleaners?

Costs vary depending on the model and specifications of the device. However, investing in a quality industrial vacuum cleaner can lead to significant savings through reduced maintenance costs and increased productivity.

5. Can an industrial vacuum cleaner be used in explosive environments?

There are specific models of industrial vacuum cleaners designed to operate in explosive environments. These devices are constructed with antistatic materials and equipped with advanced safety systems to prevent fires and explosions.

In conclusion, professional industrial vacuum cleaners are essential tools for machine shops, helping to create a safer and more productive working environment. Choosing the right model, combined with regular maintenance, ensures optimal performance and an overall improvement in air quality.

Read More Read Less