Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Workshop equipment

- Home

- Workshop equipment

- Belt sanders

Belt sanders

Professional belt sanders: a complete guide for machine shops

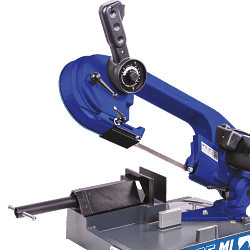

In the world of machine shops, efficiency and precision are key elements to guarantee the quality of the work performed. Among the indispensable tools for achieving these goals, professional belt sanders occupy a prominent place. Thanks to their versatility and power, these machines are able to meet the most diverse requirements, from finishing metal surfaces to preparing components for painting. In this in-depth look, we will explore in detail what professional belt sanders are, what they are used for, how they are used and what advantages they offer, also answering frequently asked questions on this topic.

What are professional belt sanders

Professional belt sanders are power tools designed for sanding and finishing surfaces. They are distinguished by the use of a continuous abrasive belt running on two rollers, allowing them to work on materials as diverse as metal, wood and plastic. Their robust construction and ability to operate at variable speeds make them suitable for intensive use in industrial and craft environments.

What professional belt sanders are used for

These tools are essential for a wide range of applications. In machine shops, belt sanders are used to remove surface imperfections, deburr sharp edges, prepare surfaces for painting and finish metal components. Their ability to work on flat and curved surfaces makes them particularly versatile, allowing high quality results to be achieved in a short time.

How professional belt sanders are used

Using a professional belt sander requires technical expertise and attention to detail. Before starting, it is essential to select the appropriate abrasive belt according to the material to be worked on and the type of finish desired. Once the belt is mounted, it is important to adjust the rotation speed according to the work to be performed. During the operation, it is essential to maintain a constant and uniform pressure on the surface, avoiding exerting too much force that could damage the material or the belt itself.

Advantages of professional belt sanders

The adoption of professional belt sanders in machine shops offers several advantages. First of all, their ability to quickly remove excess material reduces processing time, increasing productivity. In addition, the precision and quality of the finish obtained helps improve the appearance and performance of machined components. Finally, the versatility of these tools allows them to tackle a wide range of applications, making them a valuable investment for any workshop.

Frequently asked questions about professional belt sanders

1. What is the difference between a belt sander and an orbital sander?

Belt sanders are ideal for quickly removing large amounts of material and for working on large, flat surfaces. Orbital sanders, on the other hand, are more suitable for finishing work on curved or irregular surfaces due to their oscillating motion.

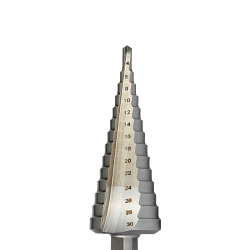

2. How do I choose the right sanding belt?

The choice of abrasive belt depends on the material to be worked on and the type of finish desired. Coarse grit belts are suitable for material removal, while fine grit belts are ideal for finishing.

3. Can a belt sander be used on wood?

Yes, belt sanders can be used on wood, but it is important to choose the appropriate abrasive belt to avoid damaging the surface.

4. What safety measures should be taken when using a belt sander?

It is essential to wear personal protective equipment such as goggles and gloves, and to ensure that the work area is well ventilated. It is also important to follow the manufacturer's instructions and keep the machine in good condition.

5. How long does an abrasive belt last?

The lifetime of an abrasive belt depends on the intensity and frequency of use, as well as the type of material being processed. It is advisable to replace the belt when you notice a reduction in sanding efficiency.

In conclusion, professional belt sanding machines are an indispensable tool for machine shops that aim to optimise production processes and improve the quality of machining. Thanks to their versatility, power and precision, these machines are able to meet the most diverse requirements, guaranteeing excellent results in every application. Investing in a professional belt sander means equipping yourself with a valuable ally to successfully meet the challenges of the industrial sector.

Read More Read LessIn the world of machine shops, efficiency and precision are key elements to guarantee the quality of the work performed. Among the indispensable tools for achieving these goals, professional belt sanders occupy a prominent place. Thanks to their versatility and power, these machines are able to meet the most diverse requirements, from finishing metal surfaces to preparing components for painting. In this in-depth look, we will explore in detail what professional belt sanders are, what they are used for, how they are used and what advantages they offer, also answering frequently asked questions on this topic.

What are professional belt sanders

Professional belt sanders are power tools designed for sanding and finishing surfaces. They are distinguished by the use of a continuous abrasive belt running on two rollers, allowing them to work on materials as diverse as metal, wood and plastic. Their robust construction and ability to operate at variable speeds make them suitable for intensive use in industrial and craft environments.

What professional belt sanders are used for

These tools are essential for a wide range of applications. In machine shops, belt sanders are used to remove surface imperfections, deburr sharp edges, prepare surfaces for painting and finish metal components. Their ability to work on flat and curved surfaces makes them particularly versatile, allowing high quality results to be achieved in a short time.

How professional belt sanders are used

Using a professional belt sander requires technical expertise and attention to detail. Before starting, it is essential to select the appropriate abrasive belt according to the material to be worked on and the type of finish desired. Once the belt is mounted, it is important to adjust the rotation speed according to the work to be performed. During the operation, it is essential to maintain a constant and uniform pressure on the surface, avoiding exerting too much force that could damage the material or the belt itself.

Advantages of professional belt sanders

The adoption of professional belt sanders in machine shops offers several advantages. First of all, their ability to quickly remove excess material reduces processing time, increasing productivity. In addition, the precision and quality of the finish obtained helps improve the appearance and performance of machined components. Finally, the versatility of these tools allows them to tackle a wide range of applications, making them a valuable investment for any workshop.

Frequently asked questions about professional belt sanders

1. What is the difference between a belt sander and an orbital sander?

Belt sanders are ideal for quickly removing large amounts of material and for working on large, flat surfaces. Orbital sanders, on the other hand, are more suitable for finishing work on curved or irregular surfaces due to their oscillating motion.

2. How do I choose the right sanding belt?

The choice of abrasive belt depends on the material to be worked on and the type of finish desired. Coarse grit belts are suitable for material removal, while fine grit belts are ideal for finishing.

3. Can a belt sander be used on wood?

Yes, belt sanders can be used on wood, but it is important to choose the appropriate abrasive belt to avoid damaging the surface.

4. What safety measures should be taken when using a belt sander?

It is essential to wear personal protective equipment such as goggles and gloves, and to ensure that the work area is well ventilated. It is also important to follow the manufacturer's instructions and keep the machine in good condition.

5. How long does an abrasive belt last?

The lifetime of an abrasive belt depends on the intensity and frequency of use, as well as the type of material being processed. It is advisable to replace the belt when you notice a reduction in sanding efficiency.

In conclusion, professional belt sanding machines are an indispensable tool for machine shops that aim to optimise production processes and improve the quality of machining. Thanks to their versatility, power and precision, these machines are able to meet the most diverse requirements, guaranteeing excellent results in every application. Investing in a professional belt sander means equipping yourself with a valuable ally to successfully meet the challenges of the industrial sector.