Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Turning tools

- Home

- Turning tools

- Knurling wheels and knurling wheel holders

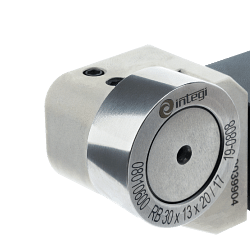

Knurling wheels and knurling wheel holders

Knurling tools and knurl holders are essential tools in the professional turning sector, an area where precision and quality are essential to achieve optimum results. These tools are mainly used in machine shops for machining cylindrical surfaces, enabling high-quality surface finishes and improving the adhesion of mechanical components.

Introduction to Knurling Wheels and Knurl Holders

Knurling wheels are tools used to create knurls on cylindrical surfaces, a process known as knurling. This process is essential to improve the grip and aesthetics of mechanical components, such as knobs and screws. Knurl holders, on the other hand, are the holders that hold knurling wheels in place during the machining process. The combination of these two tools allows for high precision and quality results.

Operation and Use of Knurling Tools

The knurling process is performed by applying pressure to the surface of the workpiece using a knurling wheel that imprints a knurling pattern. This pattern can vary depending on the type of knurling wheel used, which can be straight, cross- or spiral-toothed. The choice of knurling wheel type depends on the specific application and the desired result.

Knurling Advantages

Knurling offers numerous advantages, including improved adhesion and grip on mechanical components, improved aesthetic appearance and increased wear resistance. In addition, knurling can increase the contact surface, thus improving force distribution and reducing the risk of slippage.

Importance of knurl holders in turning

Knurl holders play a crucial role in the knurling process, as they ensure the stability and precision of the knurling wheel during machining. They are designed to withstand the forces applied during the process and to hold the knurling wheel in the correct position, thus ensuring uniform, high-quality knurling.

Selecting the right knurling wheel and knurl holder

The selection of the right knurling wheel and knurl holder is crucial for optimal results. It is important to consider the workpiece material, the type of knurling desired and the technical specifications of the application. In addition, the quality of the materials used in the manufacture of knurling wheels and knurl holders directly influences the durability and effectiveness of the tools.

Maintenance and Care of Knurling Tools

To ensure the longevity and efficiency of knurling tools and knurl holders, regular maintenance is essential. This includes cleaning the tools after each use, inspecting them for any signs of wear or damage, and lubricating moving parts to prevent corrosion and premature wear.

Frequently asked questions about knurling

1. What materials can be knurled?

Knurling can be applied to a wide range of materials, including ferrous and non-ferrous metals, plastics and wood. However, the choice of knurling wheel and knurling holder must be adapted to the specific material in order to avoid damage or unsatisfactory results.

2. What is the difference between straight and crossed knurling wheels?

Straight-tooth knurling wheels create a linear knurling pattern, while cross-tooth knurling wheels produce a diamond pattern. The choice between the two depends on the application and desired aesthetics.

3. How is the correct knurling pressure determined?

The correct pressure depends on the workpiece material and the type of knurling wheel used. It is important to follow the manufacturer's specifications and, if necessary, carry out preliminary tests to determine the optimal pressure.

Conclusion

Knurling wheels and knurling wheel holders are indispensable tools for machine shops engaged in professional turning. Their correct selection, use and maintenance are essential to ensure high quality and long-lasting results. With a thorough understanding of their functions and advantages, companies can optimise their machining processes and improve the quality of their end products.

Read More Read LessIntroduction to Knurling Wheels and Knurl Holders

Knurling wheels are tools used to create knurls on cylindrical surfaces, a process known as knurling. This process is essential to improve the grip and aesthetics of mechanical components, such as knobs and screws. Knurl holders, on the other hand, are the holders that hold knurling wheels in place during the machining process. The combination of these two tools allows for high precision and quality results.

Operation and Use of Knurling Tools

The knurling process is performed by applying pressure to the surface of the workpiece using a knurling wheel that imprints a knurling pattern. This pattern can vary depending on the type of knurling wheel used, which can be straight, cross- or spiral-toothed. The choice of knurling wheel type depends on the specific application and the desired result.

Knurling Advantages

Knurling offers numerous advantages, including improved adhesion and grip on mechanical components, improved aesthetic appearance and increased wear resistance. In addition, knurling can increase the contact surface, thus improving force distribution and reducing the risk of slippage.

Importance of knurl holders in turning

Knurl holders play a crucial role in the knurling process, as they ensure the stability and precision of the knurling wheel during machining. They are designed to withstand the forces applied during the process and to hold the knurling wheel in the correct position, thus ensuring uniform, high-quality knurling.

Selecting the right knurling wheel and knurl holder

The selection of the right knurling wheel and knurl holder is crucial for optimal results. It is important to consider the workpiece material, the type of knurling desired and the technical specifications of the application. In addition, the quality of the materials used in the manufacture of knurling wheels and knurl holders directly influences the durability and effectiveness of the tools.

Maintenance and Care of Knurling Tools

To ensure the longevity and efficiency of knurling tools and knurl holders, regular maintenance is essential. This includes cleaning the tools after each use, inspecting them for any signs of wear or damage, and lubricating moving parts to prevent corrosion and premature wear.

Frequently asked questions about knurling

1. What materials can be knurled?

Knurling can be applied to a wide range of materials, including ferrous and non-ferrous metals, plastics and wood. However, the choice of knurling wheel and knurling holder must be adapted to the specific material in order to avoid damage or unsatisfactory results.

2. What is the difference between straight and crossed knurling wheels?

Straight-tooth knurling wheels create a linear knurling pattern, while cross-tooth knurling wheels produce a diamond pattern. The choice between the two depends on the application and desired aesthetics.

3. How is the correct knurling pressure determined?

The correct pressure depends on the workpiece material and the type of knurling wheel used. It is important to follow the manufacturer's specifications and, if necessary, carry out preliminary tests to determine the optimal pressure.

Conclusion

Knurling wheels and knurling wheel holders are indispensable tools for machine shops engaged in professional turning. Their correct selection, use and maintenance are essential to ensure high quality and long-lasting results. With a thorough understanding of their functions and advantages, companies can optimise their machining processes and improve the quality of their end products.