< Turning tools Inserts for grooving and shearing

Grooving and parting-off inserts represent a fundamental element in the machining landscape, offering precise and reliable solutions for a wide range of industrial applications. These tools, essential for machine shops, are designed to guarantee efficiency and precision, two indispensable characteristics in the industrial production sector.

Understanding grooving and parting inserts

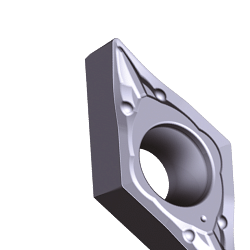

Grooving and parting inserts are components mainly used in turning and milling operations. Their main function is to make clean, precise cuts in metallic and non-metallic materials, allowing grooving and parting-off of parts with a high degree of accuracy. These inserts are made of highly resistant materials, such as tungsten carbide, which guarantee long life and exceptional wear resistance.

Applications and advantages of grooving and parting inserts

The applications of grooving and parting inserts are diverse, ranging from the production of automotive components to the manufacture of parts for the aerospace industry. One of the main advantages of using these inserts is the ability to perform complex machining operations with a high degree of precision, minimising material waste and optimising production times.

In addition, the use of high quality inserts allows the surface finish of machined parts to be improved, a crucial aspect in industries where the aesthetics and functionality of the end product are paramount. The ability to easily replace worn inserts without having to change the entire tool is a further advantage in terms of cost and downtime.

Selection of inserts: criteria and considerations

The choice of grooving and parting-off inserts must be made taking into account several factors, including the type of material to be machined, the technical specifications of the machine used and the operating conditions. It is essential to select inserts with appropriate geometries and coatings to ensure optimum performance and longer tool life.

For example, when machining hard and abrasive materials, it is advisable to opt for inserts with titanium nitride coatings or other ceramic materials, which offer greater wear resistance. Furthermore, the geometry of the insert should be chosen according to the type of machining to be performed, considering parameters such as rake angle and corner radius.

Insert usage and maintenance techniques

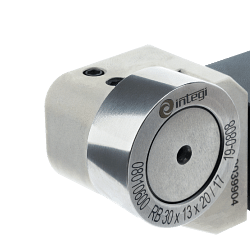

To get the most out of the performance of grooving and parting inserts, proper usage techniques and maintenance are essential. The inserts must be installed with precision, ensuring that they are properly secured and aligned to avoid excessive vibration during machining.

Regular maintenance of the inserts includes thorough cleaning to remove material residue and periodic inspection for wear. It is important to replace damaged or worn inserts in a timely manner to avoid compromising work quality and possible damage to the machine.

Frequently asked questions about grooving and parting inserts

1. What are the most common materials used for inserts?

Inserts are commonly made of tungsten carbide, ceramic and cermet, materials that offer high resistance to wear and heat.

2. How can I improve the life of the inserts?

To improve the life of the inserts, it is advisable to use appropriate lubricants during machining, select the right coating for the material to be machined and maintain an appropriate cutting speed.

3. What is the difference between grooving and parting inserts?

Grooving inserts are designed to create grooves or furrows in the material, while parting inserts are used to separate pieces or cut material into sections.

4. Can the same inserts be used for different materials?

Although some inserts can be versatile, it is preferable to use specific inserts for each type of material to ensure optimal performance and longer tool life.

5. What are the wear signs of the inserts?

Signs of wear include a reduction in surface finish quality, increased vibration during machining and the presence of chips or cracks on the insert.

Conclusions

Grooving and parting inserts are indispensable tools in machine shops, offering efficient and precise solutions for a wide range of industrial applications. The correct choice and use of these inserts can significantly improve the quality of the end product and optimise production processes. Investing in high quality inserts and adopting proper maintenance practices are key steps to ensure success and competitiveness in the machining industry.

Read More Read Less