< Clamping systems Spindles SK DIN 69871

SK DIN 69871 spindles for CNC are an essential part of the precision machining landscape. These components, which are essential for the correct operation of CNC machines, are designed to guarantee high precision and reliability, essential elements for modern machine shops. In this in-depth look, we will explore in detail what SK DIN 69871 spindles are, what they are used for, how they are used, the benefits of using them and answer some of the most frequently asked questions on this topic.

Understanding SK DIN 69871 spindles

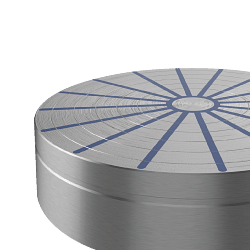

SK DIN 69871 spindles are clamping devices mainly used in CNC machine tools. Their main function is to hold tools firmly in position during machining operations, thus ensuring precision and stability. The term 'SK' refers to the conical shape of the spindle, while 'DIN 69871' is the German standard that defines the technical and dimensional specifications of these components.

The importance of spindles in CNC machining

In CNC machining, precision is everything. A quality spindle such as the SK DIN 69871 ensures that the tool is perfectly aligned and stable, minimising vibration and improving the quality of the workpiece surface finish. In addition, the use of DIN-compliant spindles ensures compatibility with a wide range of machines and tools, making the production process more flexible and efficient.

Benefits of using SK DIN 69871 spindles

There are several advantages to using SK DIN 69871 spindles. Firstly, their robust construction and dimensional accuracy ensure a long service life and a reduction in machine downtime due to replacements or repairs. In addition, their ability to maintain constant and uniform clamping reduces tool wear, contributing to lower overall operating costs. Finally, compatibility with different types of CNC machines makes these spindles a versatile choice for machine shops working with a variety of materials and applications.

Correct use of SK DIN 69871 spindles

To get the most out of SK DIN 69871 spindles, it is essential to follow certain operational guidelines. First of all, it is important to ensure that the spindle is correctly installed and the tool is properly tightened. Regular inspection of the spindle's condition and proper maintenance are essential to prevent wear problems and ensure optimum performance. In addition, it is advisable to use appropriate lubricants to reduce friction and prolong spindle life.

Frequently asked questions about SK DIN 69871 spindles

1. What is the difference between an SK DIN 69871 chuck and other types of chucks?

SK DIN 69871 spindles are designed according to standardised specifications that guarantee greater precision and compatibility than other spindle types. Their conical shape and dimensional specifications make them particularly suitable for CNC applications.

2. How do I know if an SK DIN 69871 spindle is suitable for my CNC machine?

It is important to check the technical specifications of the CNC machine and compare them with those of the spindle. In general, SK DIN 69871 spindles are compatible with most CNC machines that support DIN standards.

3. What materials can be machined with SK DIN 69871 spindles?

These spindles are suitable for a wide range of materials, including ferrous and non-ferrous metals, plastics and composite materials. The choice of the appropriate tool in combination with the chuck is crucial for optimum results.

4. How often should I replace an SK DIN 69871 chuck?

The frequency of replacement depends on usage and operating conditions. However, with proper maintenance, SK DIN 69871 spindles can last for several years. It is advisable to carry out regular checks for signs of wear or damage.

5. Can a damaged SK DIN 69871 spindle be repaired?

In some cases, damaged spindles can be repaired, but it is often more cost-effective to replace them to ensure maximum precision and safety. Consult a specialist to assess your specific situation.

Conclusion

SK DIN 69871 CNC spindles are an essential component for machine shops seeking to optimise the precision and efficiency of their operations. Thanks to their robust construction and compatibility with a wide range of machines and tools, these spindles are a reliable choice for precision machining. By following operational and maintenance guidelines, workshops can maximise the benefits of using SK DIN 69871 spindles while ensuring high quality production and reduced operating costs.

Read More Read Less