< Clamping systems Chucks MAS 403 BT

MAS 403 BT Chucks: Innovation and Precision for Machine Shops

In the world of machine shops, efficiency and precision are key elements in ensuring quality work and customer satisfaction. MAS 403 BT spindles are an essential component for machine tools, offering an advanced solution for tool clamping. In this in-depth article, we will explore in detail what MAS 403 BT spindles are, what they are used for, how they are used, the advantages they offer and answer some of the most frequently asked questions on this topic.

What are MAS 403 BT spindles?

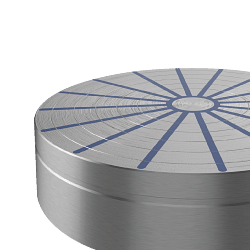

MAS 403 BT chucks are clamping devices used in machine tools to clamp cutting tools. The term 'MAS 403 BT' refers to a Japanese standard that defines the technical specifications for these chucks, ensuring optimum compatibility and performance. These spindles are designed to offer high precision and stability during machining operations, minimising vibration and improving the quality of the finished product.

Using MAS 403 BT spindles in machine tools

MAS 403 BT spindles are widely used in a variety of machine tools, including milling machines, lathes and CNC machining centres. Their main function is to hold the cutting tool firmly in position during machining operations. This is critical to ensure that the tool maintains its intended trajectory, avoiding deviations that could compromise cutting accuracy.

Advantages of MAS 403 BT spindles

There are several advantages to using MAS 403 BT spindles in machine shops. Firstly, their standardised design ensures universal compatibility with a wide range of tools and machines, facilitating integration into existing processes. In addition, their ability to reduce vibration during machining improves the surface finish of the workpiece, reducing the need for additional finishing operations.

Another significant advantage is their durability. MAS 403 BT spindles are made of high-quality materials that resist wear and deformation, ensuring a long service life and reducing maintenance costs. In addition, their ease of installation and replacement minimises machine downtime, increasing overall workshop productivity.

How to choose the right MAS 403 BT spindle

Choosing the right MAS 403 BT spindle for your needs depends on several factors, including the type of machine tool, the type of machining to be performed and the specifications of the cutting tool. It is important to consider the spindle diameter, length and type of attachment, making sure they are compatible with the tool and machine in use. In addition, it is advisable to evaluate the quality of the material and the reputation of the manufacturer to ensure the reliability and durability of the spindle.

Frequently asked questions about MAS 403 BT spindles

1. What is the difference between a MAS 403 BT spindle and other types of spindles?

MAS 403 BT spindles are distinguished by their standardised design, which guarantees compatibility and optimum performance. Compared to other spindle types, they offer greater precision and stability, reducing vibration during machining.

2. How do I install a MAS 403 BT spindle?

Installing a MAS 403 BT spindle is a relatively simple process. It is important to follow the manufacturer's instructions and ensure that the spindle is correctly aligned and tightened to avoid problems during machining.

3. What are the most common applications for MAS 403 BT spindles?

MAS 403 BT spindles are commonly used in milling, turning and drilling applications, especially in production environments that require high precision and quality of the finished product.

4. How is a MAS 403 BT spindle serviced?

Maintenance of MAS 403 BT spindles includes regular cleaning to remove chips and debris, lubrication to prevent wear and periodic inspection for signs of damage or wear.

5. What are the signs that indicate that a MAS 403 BT spindle needs to be replaced?

Signs that indicate the need to replace a spindle include excessive vibration during machining, difficulty in clamping the tool and visible signs of wear or damage on the spindle itself.

Conclusion

MAS 403 BT spindles are a crucial component for machine shops aiming to optimise the precision and efficiency of their operations. Thanks to their standardised design and the many advantages they offer, these spindles are an excellent choice for a wide range of machining applications. Choosing the right spindle and keeping it in good condition is essential to ensure the quality of work and longevity of machine tools. With a thorough understanding of their features and benefits, workshops can significantly improve their operations and meet customer needs more effectively.

Read More Read Less