< Clamping systems Chucks HSK-A DIN 69893A

High-precision HSK-A DIN 69893A spindles are a crucial element in the modern machine shop landscape. These tools, known for their precision and reliability, are essential for ensuring high quality machining and optimising production processes. In this in-depth look, we will explore in detail what HSK-A spindles are, what they are used for, how they are used, the advantages they offer and answer some of the most frequently asked questions on this topic.

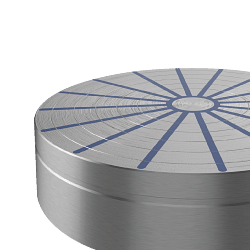

Understanding HSK-A DIN 69893A spindles

HSK-A DIN 69893A spindles are clamping devices mainly used in machine tools to clamp cutting tools. The abbreviation HSK stands for 'Hohl-Schaft-Kegel', which means 'hollow-shank cone' in German. This design was developed to improve precision and stability during machining operations. DIN 69893A defines the technical and dimensional specifications of these spindles, ensuring compatibility and interchangeability between different manufacturers.

Functionality and applications of HSK-A spindles

HSK-A spindles are designed to provide a rigid and precise connection between the machine tool and the cutting tool. This connection is crucial for reducing vibration and improving the quality of the machined surface. Thanks to their hollow-shank design, HSK-A spindles offer greater rigidity than conventional spindles, making them ideal for high-speed applications and machining requiring tight tolerances.

Typical applications for HSK-A spindles include milling, drilling and turning in industries such as aerospace, automotive and mould and die production. Their ability to maintain high accuracy even at high rotational speeds makes them particularly suitable for precision machining.

Advantages of HSK-A DIN 69893A spindles

One of the main advantages of HSK-A spindles is their ability to ensure an extremely rigid connection between the tool and the machine. This results in greater precision and reduced vibration, which in turn improves machining quality and extends tool life. In addition, HSK-A spindles offer quick and easy tool change, reducing downtime and increasing production efficiency.

Another significant advantage is their compatibility with modern machine tools. Thanks to DIN 69893A, HSK-A spindles can be used with a wide range of machines, providing flexibility and versatility in machining operations.

Correct use of HSK-A spindles

To fully exploit the advantages of HSK-A spindles, it is essential to use them correctly. First of all, it is important to ensure that the spindle is compatible with the machine tool and the cutting tool. Also, it is essential to follow the manufacturer's instructions for installing and maintaining the spindle.

During installation, it is important to check that the spindle is mounted correctly and that there is no play or misalignment. Incorrect mounting can compromise the accuracy and stability of the system, leading to unsatisfactory machining results.

Frequently asked questions about HSK-A spindles

1. What is the difference between HSK-A spindles and other spindle types?

HSK-A spindles offer greater rigidity and precision than conventional spindles due to their hollow shank design. This makes them ideal for high-speed applications and precision machining.

2. How can I guarantee the maximum service life of my HSK-A spindle?

To ensure maximum spindle life, it is important to perform regular maintenance, following the manufacturer's instructions. In addition, it is essential to avoid excessive overloading and to ensure that the spindle is always mounted correctly.

3. Are HSK-A spindles compatible with all machine tools?

HSK-A spindles are designed to be compatible with a wide range of modern machine tools. However, it is important to check compatibility with your specific machine before purchase.

4. What are the most common applications for HSK-A spindles?

HSK-A spindles are commonly used in milling, drilling and turning applications in industries such as aerospace, automotive and mould and die making.

5. How can I improve the accuracy of my machining operations using HSK-A spindles?

To improve machining accuracy, it is important to ensure that the spindle is mounted correctly and that the cutting tool is well secured. In addition, it is essential to use high quality tools and follow best machining practices.

Conclusions

High-precision HSK-A DIN 69893A spindles are essential tools for machine shops that wish to improve the quality of their machining operations and increase production efficiency. Due to their rigidity, precision and compatibility with modern machine tools, these spindles offer numerous advantages over conventional spindles. By using HSK-A spindles correctly and following best maintenance practices, workshops can achieve superior machining results and extend the service life of their tools.

Read More Read Less