Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Clamping systems

- Home

- Clamping systems

- Chucks DIN 2080 and cylindrical

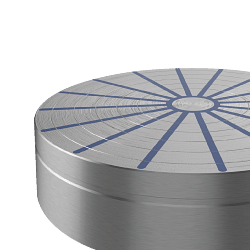

Chucks DIN 2080 and cylindrical

DIN 2080 and cylindrical chucks are essential components in the machine tool landscape, fundamental tools for machine shops that strive for excellence in material machining. These devices, although they may seem simple in their design, contain a technical complexity that makes them indispensable for ensuring precision, efficiency and safety in turning, milling and drilling operations.

The importance of DIN 2080 and cylindrical spindles

In the context of machine tools, spindles play a crucial role. They are responsible for clamping tools, ensuring that they remain firmly in place during machining operations. DIN 2080 spindles, in particular, are designed according to international standards that ensure their interchangeability and compatibility with a wide range of machine tools. This standardisation not only facilitates the replacement and upgrading of components, but also ensures that performance is optimal, regardless of the machine manufacturer.

Technical characteristics of DIN 2080 spindles

DIN 2080 spindles are characterised by a number of technical specifications that define their effectiveness. These include the ability to maintain high concentricity accuracy, which is essential to avoid unwanted vibrations that could compromise machining quality. In addition, their robust construction and the use of high-quality materials ensure a long service life, minimising the need for maintenance and replacement.

Advantages of using cylindrical spindles

Cylindrical spindles, on the other hand, offer a versatility that makes them suitable for a wide range of applications. Their ability to adapt to different types of tools and materials makes them ideal for workshops requiring flexibility in machining operations. Furthermore, thanks to their simple yet effective design, cylindrical spindles are easy to install and adjust, reducing downtime and increasing overall productivity.

Practical applications in machine shops

In machine shops, the use of DIN 2080 and cylindrical spindles is essential to ensure that machining operations are performed with maximum precision and safety. These components are used in a variety of machines, including lathes, milling machines and drills, and are essential for operations requiring a high degree of accuracy, such as the production of components for the automotive and aerospace industries.

Spindle maintenance and care

To ensure that DIN 2080 and cylindrical spindles maintain their optimum performance, it is essential to follow regular maintenance practices. This includes periodic cleaning to remove swarf and debris that could affect operation, as well as lubrication to prevent wear and corrosion. In addition, it is important to regularly inspect spindles for signs of damage or wear, taking prompt action to avoid more serious problems.

Frequently asked questions about DIN 2080 and cylindrical spindles

One of the most common questions concerns the compatibility of DIN 2080 spindles with existing machine tools. Due to their standardised design, these spindles are compatible with most modern machines, making it easy to integrate them into existing workshops. Another frequently asked question concerns the difference between DIN 2080 and cylindrical spindles. While the former are designed according to specific standards, cylindrical spindles offer greater flexibility in terms of applications and adaptability.

Conclusions

In summary, DIN 2080 and cylindrical spindles are essential components for machine shops that aim to optimise their machining operations. Thanks to their precision, robustness and versatility, these spindles not only improve the quality of the end product, but also help reduce operating costs and increase productivity. Investing in high-quality spindles is therefore a strategic choice for any workshop wishing to remain competitive in today's market.

Read More Read LessThe importance of DIN 2080 and cylindrical spindles

In the context of machine tools, spindles play a crucial role. They are responsible for clamping tools, ensuring that they remain firmly in place during machining operations. DIN 2080 spindles, in particular, are designed according to international standards that ensure their interchangeability and compatibility with a wide range of machine tools. This standardisation not only facilitates the replacement and upgrading of components, but also ensures that performance is optimal, regardless of the machine manufacturer.

Technical characteristics of DIN 2080 spindles

DIN 2080 spindles are characterised by a number of technical specifications that define their effectiveness. These include the ability to maintain high concentricity accuracy, which is essential to avoid unwanted vibrations that could compromise machining quality. In addition, their robust construction and the use of high-quality materials ensure a long service life, minimising the need for maintenance and replacement.

Advantages of using cylindrical spindles

Cylindrical spindles, on the other hand, offer a versatility that makes them suitable for a wide range of applications. Their ability to adapt to different types of tools and materials makes them ideal for workshops requiring flexibility in machining operations. Furthermore, thanks to their simple yet effective design, cylindrical spindles are easy to install and adjust, reducing downtime and increasing overall productivity.

Practical applications in machine shops

In machine shops, the use of DIN 2080 and cylindrical spindles is essential to ensure that machining operations are performed with maximum precision and safety. These components are used in a variety of machines, including lathes, milling machines and drills, and are essential for operations requiring a high degree of accuracy, such as the production of components for the automotive and aerospace industries.

Spindle maintenance and care

To ensure that DIN 2080 and cylindrical spindles maintain their optimum performance, it is essential to follow regular maintenance practices. This includes periodic cleaning to remove swarf and debris that could affect operation, as well as lubrication to prevent wear and corrosion. In addition, it is important to regularly inspect spindles for signs of damage or wear, taking prompt action to avoid more serious problems.

Frequently asked questions about DIN 2080 and cylindrical spindles

One of the most common questions concerns the compatibility of DIN 2080 spindles with existing machine tools. Due to their standardised design, these spindles are compatible with most modern machines, making it easy to integrate them into existing workshops. Another frequently asked question concerns the difference between DIN 2080 and cylindrical spindles. While the former are designed according to specific standards, cylindrical spindles offer greater flexibility in terms of applications and adaptability.

Conclusions

In summary, DIN 2080 and cylindrical spindles are essential components for machine shops that aim to optimise their machining operations. Thanks to their precision, robustness and versatility, these spindles not only improve the quality of the end product, but also help reduce operating costs and increase productivity. Investing in high-quality spindles is therefore a strategic choice for any workshop wishing to remain competitive in today's market.