< Chemical, adhesives and sealants Welding machines

Professional welding machines are a crucial element in the modern machine shop landscape. These tools, essential for metalworking, offer a combination of precision, efficiency and reliability that is hard to match. In this in-depth look, we will explore in detail what professional welding machines are, what they are used for, how they are used, the advantages they offer, and answer some of the most frequently asked questions about these indispensable tools.

Introduction to professional welding machines

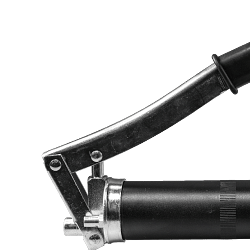

Professional welders are devices designed to join two or more pieces of metal through fusion. They use an intense heat source to melt the materials, which then solidify to form a strong joint. These tools are widely used in various industries, including construction, automotive manufacturing, aerospace and many other applications that require strong and durable metal joints.

Types of professional welding machines

There are different types of professional welding machines, each with specific characteristics that make them suitable for particular applications. Among the most common are:

- Coated electrode (MMA) welders: These welders are known for their versatility and ability to operate in difficult conditions. They use a coated electrode that acts as a filler material and protection for the weld pool.

- Continuous Wire Welders (MIG/MAG): Ideal for jobs requiring speed and precision, these welders use a continuous wire as filler material, which is automatically fed through the torch.

- TIG (Tungsten Inert Gas) Welders: Offer high quality, high precision welding, using a non-consumable tungsten electrode and an inert gas to protect the weld pool.

- Resistance Welders: Used mainly for welding thin sheets, these welders exploit the electrical resistance of materials to generate heat and melt metals.

Advantages of professional welders

The use of professional welders offers numerous advantages, including:

- Precision and control: Modern welding machines are equipped with advanced technologies that allow precise control of welding parameters, ensuring high-quality joints.

- Operational efficiency: Thanks to their ability to operate at high speeds, professional welding machines reduce processing times, increasing productivity.

- Versatility: With the ability to work on different materials and thicknesses, these welders are suitable for a wide range of industrial applications.

- Reliability: Designed to withstand demanding working conditions, professional welders offer consistent, long-lasting performance.

Use of professional welders in machine shops

In machine shops, professional welders are indispensable tools for manufacturing complex metal components. Their ability to create strong and precise joints is crucial to ensure the safety and reliability of finished products. Operators must be properly trained to use these tools safely and effectively, following current safety guidelines and regulations.

Frequently asked questions about professional welding machines

1. What is the difference between MIG and TIG welding?

MIG welding uses a continuous wire as a filler material, whereas TIG welding uses a non-consumable tungsten electrode and an inert gas. MIG welding is generally faster, while TIG welding offers greater precision.

2. What are the most common materials that can be welded with professional welding machines?

Professional welding machines can be used to weld a wide range of materials, including steel, aluminium, copper and special alloys.

3. How do I choose the right welding machine for a specific application?

The choice of welding machine depends on several factors, including the type of material to be welded, the thickness of the material, the type of joint required and the working conditions. It is important to consult an expert to determine the best solution for your needs.

4. What safety measures should be taken when using welding machines?

It is essential to wear personal protective equipment, such as welding masks, gloves and fireproof clothing. In addition, it is important to work in a well-ventilated area and to follow all applicable safety regulations.

Conclusion

Professional welding machines are essential tools for machine shops and industry in general. They offer a combination of precision, efficiency and reliability that is crucial for the production of high-quality metal components. With a thorough understanding of their features and benefits, companies can optimise their production processes and guarantee excellent results. Investing in high-quality professional welders and operator training is a strategic choice that can lead to significant improvements in productivity and end-product quality.

Read More Read Less