< Chemical, adhesives and sealants Lubrication accessories

Industrial lubrication accessories: a complete guide for machine shops

In the world of machine shops, industrial lubrication plays a crucial role in ensuring the proper functioning and longevity of machines. Industrial lubrication accessories are essential tools that facilitate this process, improving operational efficiency and reducing downtime. In this in-depth look, we will explore in detail what these accessories are, what they are for, how they are used and what benefits they offer.

What are industrial lubrication accessories?

Industrial lubrication accessories include a wide range of tools and devices designed to apply lubricants in a precise and controlled manner. These accessories include grease pumps, oilers, grease nipples, central lubrication systems and more. Each accessory is designed to meet specific needs, ensuring that each mechanical component receives the right amount of lubricant.

The importance of lubrication in mechanical workshops

Lubrication is essential to reduce friction between the moving parts of machines, preventing wear and overheating. Without proper lubrication, machines can suffer significant damage, leading to costly repairs and downtime. Industrial lubrication accessories ensure that lubricant is applied evenly and consistently, optimising machine performance.

Types of lubrication accessories

There are different types of industrial lubrication accessories, each with specific characteristics and applications:

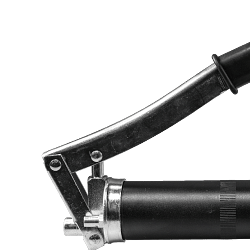

1. Grease pumps: Used to apply grease to bearings and other surfaces, grease pumps can be manual, pneumatic or electric. They offer precise and controlled application of the lubricant.

2. Oilers: These devices are designed to apply lubricating oils to surfaces and components. They can be equipped with transparent reservoirs to monitor the oil level.

3. Grease guns: Used to apply grease in hard-to-reach places, grease guns are essential tools for preventive maintenance.

4. Centralised lubrication systems: These systems automate the lubrication process, distributing lubricant to several points simultaneously. They are ideal for complex machines with numerous lubrication points.

5. Lubricant management accessories: These include filters, tanks and monitoring devices that help keep the lubricant clean and monitor its use.

How to use industrial lubrication accessories

The correct use of industrial lubrication accessories is essential to ensure the effectiveness of the lubrication process. Here are some key steps:

- Lubricant selection: It is crucial to choose the right lubricant for the specific application. Consider factors such as operating temperature, load and speed of moving parts.

- Precise application: Use the appropriate accessories to apply the lubricant evenly. Grease pumps and oilers must be calibrated to deliver the correct amount of lubricant.

- Maintenance of accessories: Lubrication accessories must be regularly cleaned and maintained to ensure optimal performance. Check filters and replace them if necessary.

Benefits of using industrial lubrication accessories

The use of industrial lubrication accessories offers numerous advantages to machine shops:

- Reduced wear: Adequate lubrication reduces friction and wear on moving parts, prolonging the service life of machines.

- Improved efficiency: Well-lubricated machines operate more efficiently, reducing energy consumption and improving overall performance.

- Reduced downtime: Preventive maintenance through regular lubrication reduces the risk of sudden breakdowns and downtime.

- Cost savings: Investing in quality lubrication accessories can reduce long-term maintenance and repair costs.

Frequently asked questions about industrial lubrication accessories

1. What is the difference between a manual and an electric grease pump?

Manual grease pumps require the physical action of the operator to dispense grease, whereas electric grease pumps automate the process, providing faster and more uniform application.

2. How do I choose the right lubricant?

The choice of lubricant depends on the specific needs of the application, including factors such as temperature, load and speed. It is advisable to consult the machine manufacturer's specifications.

3. How often should lubrication accessories be maintained?

Lubrication accessories should be maintained regularly, following the manufacturer's recommendations and specific operational requirements.

4. What are the signs of inadequate lubrication?

Unusual noises, overheating and excessive wear of parts are common signs of inadequate lubrication.

5. Can the lubrication process be fully automated?

Yes, centralised lubrication systems can automate the process, ensuring an even distribution of the lubricant to all necessary points.

In conclusion, industrial lubrication accessories are indispensable tools for machine shops wishing to optimise the performance of their machines. Investing in these accessories and using them correctly can lead to significant improvements in operational efficiency, cost reduction and equipment longevity.

Read More Read Less