< Pneumatics Pressure regulators

Pneumatic pressure regulators are essential components in many industrial applications, especially in machine shops, where precision and reliability are paramount. These devices are designed to maintain compressed air pressure at a constant level, thus ensuring the proper functioning of pneumatic equipment. In this in-depth look, we will explore in detail what pneumatic pressure regulators are, how they work, their advantages and main applications, as well as answer some frequently asked questions.

Understanding pneumatic pressure regulators

Pneumatic pressure regulators are devices that reduce and stabilise the pressure of compressed air in a pneumatic system. They are essential to ensure that the pressure does not exceed the safety or operating efficiency levels of the equipment. A typical pressure regulator consists of a body, a diaphragm, a regulating spring and a control valve. The inlet air pressure is reduced to a desired level, which can be adjusted by means of a knob or adjustment screw.

Operation and use in pneumatic systems

The operation of a pneumatic pressure regulator is based on a balance between spring force and air pressure. When the outlet pressure exceeds the set level, the valve closes to reduce the air flow, thus keeping the pressure constant. Conversely, if the pressure drops below the desired level, the valve opens to increase the air flow. This continuous feedback mechanism ensures that the pressure remains stable, regardless of changes in inlet pressure or fluctuations in air consumption.

Advantages of pneumatic pressure regulators

The use of pneumatic pressure regulators offers numerous advantages. Firstly, they improve energy efficiency by reducing compressed air consumption, which translates into operating cost savings. In addition, they protect pneumatic equipment from damage caused by excessive pressure, thus extending its service life. The pressure stability provided by the regulators also improves the accuracy and reliability of operations, reducing downtime and increasing overall productivity.

Applications in machine shops

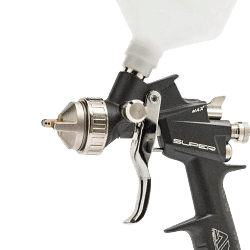

In machine shops, pneumatic pressure regulators find application in a wide range of tools and machinery. They are used in spray painting systems, where constant pressure is crucial to achieving a uniform finish. They are also used in lifting and handling equipment, where safe and efficient operation depends on controlled air pressure. In automation and control systems, pressure regulators are also essential to ensure the precise operation of actuators and valves.

Frequently asked questions about pneumatic pressure regulators

1. How do I choose a pneumatic pressure regulator?

The choice of a pneumatic pressure regulator depends on various factors, including the desired inlet and outlet pressure, the required air flow and the specifications of the application. It is also important to consider compatibility with the materials and environmental conditions in which the regulator will be used.

2. What are the signals of a defective pressure regulator?

Signs of a defective pressure regulator include pressure fluctuations, air leaks, unusual noises and a slow response to pressure changes. In the event of a malfunction, it is advisable to service or replace the regulator to avoid damage to the equipment.

3. Is it possible to adjust the pressure without interrupting system operation?

Yes, many pneumatic pressure regulators allow pressure adjustment without interrupting system operation. However, it is important to follow the manufacturer's instructions to ensure safe and accurate adjustment.

Conclusions

Pneumatic pressure regulators are crucial components for the efficient and safe operation of pneumatic equipment in machine shops. Their ability to maintain a constant pressure not only protects equipment from damage, but also improves operational efficiency and reduces costs. Understanding their operation and applications can help companies optimise their processes and ensure a safe and productive working environment.

Read More Read Less