Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Pneumatics

- Home

- Pneumatics

- Compressors

Compressors

Professional air compressors are a staple in machine shops, offering versatility and efficiency that are hard to match. These tools are designed to provide high-pressure compressed air, essential for a wide range of industrial and craft applications. In this in-depth look, we will explore in detail what professional air compressors are, how they work, their benefits and answers to frequently asked questions.

Understanding professional air compressors

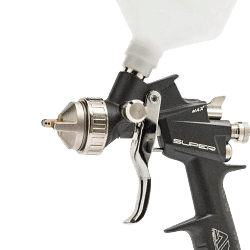

Professional air compressors are mechanical devices that convert energy (usually from an electric motor, diesel engine or petrol engine) into stored potential energy in the form of compressed air. This compressed air can be used to power a variety of pneumatic tools, such as drills, screwdrivers, spray guns and more. The ability to provide a constant flow of air at high pressure makes air compressors indispensable in many industrial applications.

How air compressors work

The operating principle of an air compressor is relatively simple. Air is drawn in from the outside environment and compressed inside a tank. This process increases the air pressure, which can then be released through a valve to power tools and machinery. There are different types of compressors, including piston, screw and vane compressors, each with specific characteristics that make them suitable for particular applications.

Advantages of professional air compressors

The use of professional air compressors offers numerous advantages. First of all, their ability to power pneumatic tools allows for greater precision and control than traditional electric tools. In addition, air compressors are generally more durable and require less maintenance, reducing long-term operating costs. Versatility is another big advantage, as a single compressor can power a wide range of tools, making it an economical investment for machine shops.

Practical applications in machine shops

In machine shops, air compressors are used for a variety of tasks. They can power metalworking tools, such as grinders and drills, as well as painting and cleaning tools. The ability to provide a constant flow of compressed air makes compressors ideal for operations requiring precision and reliability. In addition, the use of compressed air reduces the risk of sparks, making air compressors a safe choice for environments where flammable materials are present.

Frequently asked questions about professional air compressors

1. What is the difference between a piston compressor and a screw compressor?

Piston compressors use a piston to compress air, whereas screw compressors use two screw rotors. Screw compressors are generally quieter and more efficient, but also more expensive.

2. How do you determine the compressor size required?

The size of the compressor depends on the type of instruments to be supplied and the amount of air required. It is important to consider both the pressure (PSI) and the air volume (CFM) required for the specific application.

3. What are the maintenance considerations for air compressors?

Regular maintenance is essential to ensure optimal compressor operation. This includes checking and replacing air filters, checking for leaks and lubricating moving parts.

4. Are air compressors suitable for domestic use?

Although professional air compressors are primarily designed for industrial applications, there are smaller, less powerful models that can be used for domestic and DIY projects.

5. What are the environmental considerations when using air compressors?

The use of air compressors can have an environmental impact, particularly in terms of energy consumption. It is important to choose energy-efficient models and adopt maintenance practices that minimise waste.

Conclusion

Professional air compressors are essential tools for machine shops, offering a combination of power, versatility and reliability. Understanding how they work and the benefits they offer can help companies optimise their operations and improve overall efficiency. With proper maintenance and a judicious choice of the right model, air compressors can be a valuable investment for any industrial business.

Read More Read LessUnderstanding professional air compressors

Professional air compressors are mechanical devices that convert energy (usually from an electric motor, diesel engine or petrol engine) into stored potential energy in the form of compressed air. This compressed air can be used to power a variety of pneumatic tools, such as drills, screwdrivers, spray guns and more. The ability to provide a constant flow of air at high pressure makes air compressors indispensable in many industrial applications.

How air compressors work

The operating principle of an air compressor is relatively simple. Air is drawn in from the outside environment and compressed inside a tank. This process increases the air pressure, which can then be released through a valve to power tools and machinery. There are different types of compressors, including piston, screw and vane compressors, each with specific characteristics that make them suitable for particular applications.

Advantages of professional air compressors

The use of professional air compressors offers numerous advantages. First of all, their ability to power pneumatic tools allows for greater precision and control than traditional electric tools. In addition, air compressors are generally more durable and require less maintenance, reducing long-term operating costs. Versatility is another big advantage, as a single compressor can power a wide range of tools, making it an economical investment for machine shops.

Practical applications in machine shops

In machine shops, air compressors are used for a variety of tasks. They can power metalworking tools, such as grinders and drills, as well as painting and cleaning tools. The ability to provide a constant flow of compressed air makes compressors ideal for operations requiring precision and reliability. In addition, the use of compressed air reduces the risk of sparks, making air compressors a safe choice for environments where flammable materials are present.

Frequently asked questions about professional air compressors

1. What is the difference between a piston compressor and a screw compressor?

Piston compressors use a piston to compress air, whereas screw compressors use two screw rotors. Screw compressors are generally quieter and more efficient, but also more expensive.

2. How do you determine the compressor size required?

The size of the compressor depends on the type of instruments to be supplied and the amount of air required. It is important to consider both the pressure (PSI) and the air volume (CFM) required for the specific application.

3. What are the maintenance considerations for air compressors?

Regular maintenance is essential to ensure optimal compressor operation. This includes checking and replacing air filters, checking for leaks and lubricating moving parts.

4. Are air compressors suitable for domestic use?

Although professional air compressors are primarily designed for industrial applications, there are smaller, less powerful models that can be used for domestic and DIY projects.

5. What are the environmental considerations when using air compressors?

The use of air compressors can have an environmental impact, particularly in terms of energy consumption. It is important to choose energy-efficient models and adopt maintenance practices that minimise waste.

Conclusion

Professional air compressors are essential tools for machine shops, offering a combination of power, versatility and reliability. Understanding how they work and the benefits they offer can help companies optimise their operations and improve overall efficiency. With proper maintenance and a judicious choice of the right model, air compressors can be a valuable investment for any industrial business.