< Milling cutters Shoulder milling cutters and inserts

CNC Straight Shoulder Cutters and Inserts: A Complete Guide for Machine Shops

In the world of machining, the use of CNC straight-shoulder milling cutters and inserts is a crucial element in ensuring precision and quality in manufacturing processes. These tools are essential for obtaining perfectly flat surfaces and right angles, which are fundamental characteristics in many industrial applications. In this in-depth article, we will explore in detail what CNC straight edge milling cutters and inserts are, how they are used, the advantages they offer and answer some of the most frequently asked questions on this topic.

What are CNC square shoulder cutters and inserts

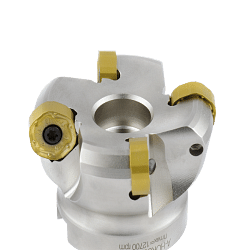

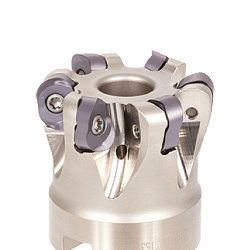

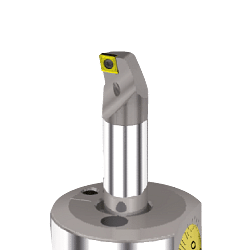

CNC straight shoulder milling cutters are cutting tools designed to machine materials such as metals, alloys and composite materials, creating flat surfaces and right angles. These cutters are mainly used in computer numerical control (CNC) machines, which guarantee high precision and repeatability in machining processes. The inserts, on the other hand, are interchangeable components mounted on the cutter, made of wear-resistant materials such as tungsten carbide or ceramic, which maintain cutting efficiency and extend tool life.

Using CNC Straight Shoulder Cutters and Inserts

The use of CNC straight-shoulder milling cutters and inserts is essential in a variety of industries, including aerospace, automotive and machinery manufacturing. These tools are used to produce components that require tight tolerances and high quality surface finishes. Straight shoulder milling cutters are particularly suitable for milling operations on shoulders, slots and pockets, where 90-degree angles need to be achieved with precision.

Advantages of CNC square shoulder cutters and inserts

The adoption of CNC straight shoulder milling cutters and inserts offers numerous advantages to machine shops. First and foremost, the precision and repeatability of CNC machining minimises scrap and improves production efficiency. Furthermore, the use of interchangeable inserts optimises production costs, as only the worn part of the tool can be replaced without having to replace the entire milling cutter. This translates into significant cost savings and greater environmental sustainability.

Advanced materials and technologies for cutters and inserts

CNC straight cutters and inserts are made from advanced materials that guarantee strength and durability. Tungsten carbide is one of the most common materials used for inserts due to its high hardness and wear resistance. In addition, coating technologies, such as titanium nitride (TiN) or aluminium titanium nitride (AlTiN), further improve insert performance by reducing friction and increasing heat resistance.

Frequently Asked Questions about CNC Straight Shoulder Cutters and Inserts

1. What are the main factors to consider when choosing CNC straight shoulder cutters and inserts?

The choice of cutters and inserts depends on several factors, including the material to be machined, the cutting speed, the depth of cut and the specifications of the CNC machine. It is important to select tools that offer an optimal balance between tool life, precision and cost.

2. How do you maintain CNC straight cutters and inserts?

Regular maintenance is essential to ensure optimum performance. Inserts should be replaced when they show signs of wear, while cutters should be cleaned and inspected periodically for damage or deformation.

3. What are the future trends in the field of CNC straight cutters and inserts?

Technological innovations are leading to the development of new materials and designs for milling cutters and inserts, with the aim of further improving the efficiency and sustainability of machining. The integration of digital technologies and the use of advanced composite materials are some of the emerging trends in this sector.

In conclusion, CNC straight-shoulder milling cutters and inserts are indispensable tools for machine shops aiming to ensure precision and quality in machining. The careful choice of tools, combined with proper maintenance, allows production processes to be optimised and excellent results to be achieved in terms of surface finish and dimensional tolerances. As technologies and materials evolve, the opportunities to further improve the performance of milling cutters and inserts are constantly growing, offering new possibilities for manufacturing industries.

Read More Read Less