Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Milling cutters

- Home

- Milling cutters

- Modular boring system

Modular boring system

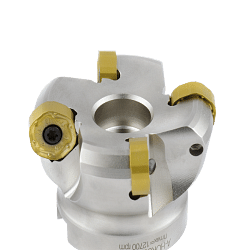

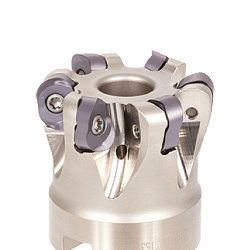

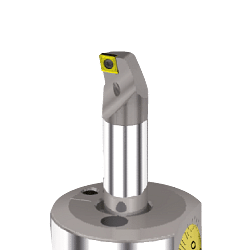

The modular CNC boring system represents one of the most significant innovations in the field of precision machining. This system is designed to optimise and improve the efficiency of boring operations, a fundamental process for producing precision holes in metal components. Deep boring is a technique that requires precision and accuracy, and the introduction of modular systems has revolutionised the way machine shops approach this challenge.

The evolution of boring: from traditional to CNC

Traditional boring, although effective, has limitations in terms of speed and accuracy. With the advent of computer numerical control (CNC) machines, the boring process has undergone a radical transformation. CNC machines offer precise and repeatable control, minimising human error and increasing productivity. However, the integration of a modular CNC boring system takes these benefits to the next level, allowing for greater flexibility and adaptability to specific production requirements.

Modular system components and functionality

A modular CNC boring system consists of several interchangeable components that can be configured according to specific project requirements. These components include cutting tools, tool holders, and extension modules that can be easily replaced or upgraded. The modularity of the system allows the machine to be quickly adapted to different boring operations, reducing setup time and increasing overall efficiency.

Advantages of using a modular system

The adoption of a modular system for CNC boring offers several advantages. Firstly, modularity allows greater operational flexibility, enabling workshops to respond quickly to changes in production specifications or new customer requirements. In addition, the ability to replace individual components reduces maintenance costs and extends machine life. Another significant benefit is the increased precision and quality of the end product, thanks to the system's ability to maintain tight and consistent tolerances.

Industrial applications and fields of use

The modular CNC boring system finds application in a wide range of industries, including aerospace, automotive, and heavy industry. In each of these sectors, precision and reliability are critical, and the modular system offers the performance necessary to meet these requirements. For example, in the aerospace industry, the boring of critical components such as engine parts requires extremely tight tolerances, which can be easily achieved with a modular system.

Optimising production processes

Integrating a modular CNC boring system into production processes allows workshops to optimise operations, reducing cycle times and improving product quality. The ability to quickly configure the machine for different boring operations means that workshops can handle a wide variety of projects without the need to invest in additional equipment. This not only reduces operating costs, but also increases the company's competitiveness in the market.

Frequently asked questions about the modular CNC boring system

Many industry professionals have questions regarding the implementation and use of a modular CNC boring system. Here are some of the most common questions:

- What are the maintenance requirements for a modular system?

Maintenance of a modular system is generally easier than with conventional systems, due to the possibility of replacing individual components. It is important to follow the manufacturer's guidelines to ensure optimal performance.

- Can a modular system be used for different types of materials?

Yes, modular systems are designed to be versatile and can be used to process a wide range of materials, including steel, aluminium, and special alloys.

- What are the costs associated with implementing a modular system?

Although the initial investment can be significant, the long-term savings in terms of operational efficiency and reduced maintenance costs make the modular system a cost-effective option.

Conclusions

The modular CNC boring system is an advanced solution for machine shops seeking to improve the accuracy and efficiency of their operations. Thanks to its flexibility and ability to quickly adapt to different production requirements, this system has become an essential element for companies operating in high-precision sectors. Adopting a modular system not only improves the quality of the end product, but also allows companies to remain competitive in an ever-changing market.

Read More Read LessThe evolution of boring: from traditional to CNC

Traditional boring, although effective, has limitations in terms of speed and accuracy. With the advent of computer numerical control (CNC) machines, the boring process has undergone a radical transformation. CNC machines offer precise and repeatable control, minimising human error and increasing productivity. However, the integration of a modular CNC boring system takes these benefits to the next level, allowing for greater flexibility and adaptability to specific production requirements.

Modular system components and functionality

A modular CNC boring system consists of several interchangeable components that can be configured according to specific project requirements. These components include cutting tools, tool holders, and extension modules that can be easily replaced or upgraded. The modularity of the system allows the machine to be quickly adapted to different boring operations, reducing setup time and increasing overall efficiency.

Advantages of using a modular system

The adoption of a modular system for CNC boring offers several advantages. Firstly, modularity allows greater operational flexibility, enabling workshops to respond quickly to changes in production specifications or new customer requirements. In addition, the ability to replace individual components reduces maintenance costs and extends machine life. Another significant benefit is the increased precision and quality of the end product, thanks to the system's ability to maintain tight and consistent tolerances.

Industrial applications and fields of use

The modular CNC boring system finds application in a wide range of industries, including aerospace, automotive, and heavy industry. In each of these sectors, precision and reliability are critical, and the modular system offers the performance necessary to meet these requirements. For example, in the aerospace industry, the boring of critical components such as engine parts requires extremely tight tolerances, which can be easily achieved with a modular system.

Optimising production processes

Integrating a modular CNC boring system into production processes allows workshops to optimise operations, reducing cycle times and improving product quality. The ability to quickly configure the machine for different boring operations means that workshops can handle a wide variety of projects without the need to invest in additional equipment. This not only reduces operating costs, but also increases the company's competitiveness in the market.

Frequently asked questions about the modular CNC boring system

Many industry professionals have questions regarding the implementation and use of a modular CNC boring system. Here are some of the most common questions:

- What are the maintenance requirements for a modular system?

Maintenance of a modular system is generally easier than with conventional systems, due to the possibility of replacing individual components. It is important to follow the manufacturer's guidelines to ensure optimal performance.

- Can a modular system be used for different types of materials?

Yes, modular systems are designed to be versatile and can be used to process a wide range of materials, including steel, aluminium, and special alloys.

- What are the costs associated with implementing a modular system?

Although the initial investment can be significant, the long-term savings in terms of operational efficiency and reduced maintenance costs make the modular system a cost-effective option.

Conclusions

The modular CNC boring system is an advanced solution for machine shops seeking to improve the accuracy and efficiency of their operations. Thanks to its flexibility and ability to quickly adapt to different production requirements, this system has become an essential element for companies operating in high-precision sectors. Adopting a modular system not only improves the quality of the end product, but also allows companies to remain competitive in an ever-changing market.