< Milling cutters High feed milling cutters and inserts

High feed milling cutters and inserts: a complete guide for machine shops

In the world of machining, efficiency and precision are key elements in guaranteeing the quality of the end product and competitiveness on the market. Among the technologies that have revolutionised the sector, high feed milling cutters and inserts occupy a prominent place. These tools, thanks to their ability to operate at higher speeds and with greater precision, are an ideal solution for machine shops aiming to optimise production processes.

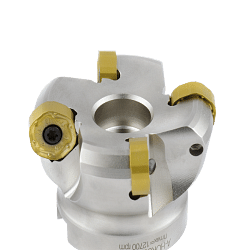

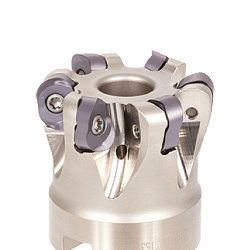

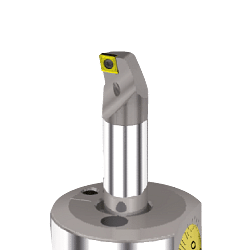

What are High Feed Milling Cutters and Inserts?

High feed milling cutters are tools designed to remove material quickly and efficiently. Unlike conventional milling cutters, they feature a design that allows them to operate at very high feed rates while reducing cutting forces. The inserts, which are the interchangeable parts of the cutters, are made of advanced materials such as tungsten carbide, which guarantees long life and superior wear resistance.

Advantages of using high feed cutters and inserts

The adoption of high feed milling cutters and inserts offers several advantages to machine shops. Firstly, the ability to operate at higher speeds results in a significant reduction in machining time, thus increasing productivity. In addition, the reduction in cutting forces minimises tool wear, prolonging tool life and reducing replacement costs. Another advantage is the possibility to achieve high quality surface finishes due to the precision of the cut.

How to use high feed cutters and inserts correctly

To fully exploit the benefits of high feed cutters and inserts, it is essential to follow certain operational guidelines. First, it is important to select the right tool according to the material to be machined and the project specifications. Choosing the correct angle of attack and feed rate is crucial to optimise tool performance. In addition, it is essential to maintain tools in good condition, performing regular checks and replacing inserts when necessary.

Applications of high feed milling cutters and inserts in machine shops

High feed milling cutters and inserts find applications in a wide range of industries. They are particularly popular in the automotive and aerospace industries, where precision and speed of machining are essential. They are also used in the production of moulds and dies, where the quality of the surface finish is paramount. Due to their versatility, these tools are also suitable for machining difficult-to-cut materials, such as titanium alloys and stainless steels.

Frequently asked questions on the use of high feed milling cutters and inserts

1. Which materials are best suited for high feed milling cutters?

High feed cutters are generally made of tungsten carbide, a material that offers excellent wear resistance and long tool life. This makes them ideal for machining hard, abrasive materials.

2. How can I improve the life of the inserts?

To prolong the life of the inserts, it is important to follow the manufacturer's recommendations regarding cutting speed and feed rate. Also, it is advisable to use a suitable coolant to reduce the heat generated during machining.

3. Can high feed milling cutters be used on CNC machines?

Yes, high feed cutters are compatible with CNC machines and can be programmed to operate at optimum speeds and feeds, ensuring accuracy and efficiency.

4. What are the signs that indicate the need to replace an insert?

Signs that indicate the need to replace an insert include a reduction in surface finish quality, increased vibration during machining and increased cutting forces.

5. What are the differences between high feed milling cutters and conventional milling cutters?

High feed cutters are designed to operate at higher feed rates than conventional cutters, reducing cutting forces and improving machining efficiency. This makes them particularly suitable for applications requiring high productivity and precision.

Conclusions

High feed milling cutters and inserts represent an advanced solution for machine shops wishing to improve the efficiency and quality of their machining operations. Thanks to their ability to operate at higher speeds and with greater precision, these tools offer significant advantages in terms of productivity and cost reduction. However, to achieve the best results, it is crucial to select the right tools and follow the appropriate operating guidelines. By adopting these technologies, machine shops can successfully meet the challenges of the modern market, ensuring high quality products and short delivery times.

Read More Read Less