Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

- Home

- Clamping systems

- Driven tool holders

Driven tool holders

ALGRA: Precision and Innovation in Machine Tools

ALGRA S.p.A. is an Italian company specialising in the production of accessories for machine tools and precision machining, with over fifty years of experience in the sector. Founded in 1974, the company has evolved over time, establishing itself as a point of reference for the international mechanical engineering industry.

With a cutting-edge production facility and a strong focus on innovation, ALGRA develops advanced technological solutions, guaranteeing high quality standards and maximum reliability for its customers.

Why choose ALGRA?

Long experience in the sector and attention to quality make ALGRA a reliable partner for companies operating in the precision mechanics sector. The main strengths include:

- High precision and reliability – Thanks to extremely accurate machining and rigorous quality controls, each product guarantees optimal performance.

- First choice materials – The company uses special steels and high performance alloys to ensure durability and resistance.

- Constant innovation – Continuous investments in research and development to improve the performance of machine tool accessories.

- Entirely Made in Italy production – All products are designed and manufactured in Italy, with machining performed using latest generation machinery.

- Customised solutions – tailor-made design to meet specific customer requirements, with the possibility of developing special tool holders and components.

ALGRA Product Range

ALGRA offers a wide range of accessories for machine tools, designed to guarantee efficiency, precision and reliability in mechanical machining.

1. Rotary and Fixed Tool Holders

ALGRA tool holders are designed for CNC lathes and guarantee high performance in terms of precision and resistance. Available in different versions:

- VDI tool holders – Ideal for CNC lathes, they guarantee maximum stability and precision.

- Tool holders with BMT connection – Designed for latest generation machines, with high structural rigidity.

- Special tool holders – Customised solutions for specific applications, made according to customer requirements.

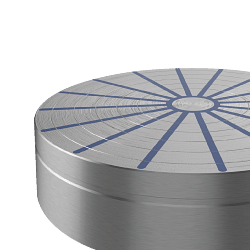

2. Tool turrets and tool discs

ALGRA tool holder turrets are designed to optimise turning and milling operations, improving production times and increasing productivity.

- Quick change turrets – Allow for quick tool replacement, reducing machine downtime.

- 24-position swivel turrets – Offer flexibility and versatility in machining operations.

- Tool holder discs – Essential elements for the rapid change of tools on CNC machines, guaranteeing precision and repeatability in machining.

3. Accessories for Lathes and Machine Tools

ALGRA produces a wide range of accessories for traditional and CNC lathes, including:

- Angular heads – Allow machining on inclined planes or in places that are difficult to reach with traditional tools.

- Vices and clamping systems – Designed to guarantee stability and safety during machining processes.

- Cooling and lubrication systems – Designed to improve cutting performance and extend tool life.

Application Sectors

ALGRA products are used in various industrial sectors, including:

- Automotive industry – Production of engine, transmission and bodywork components.

- Aerospace – Machining of high-strength materials for the aeronautical sector.

- Precision mechanics – Production of high-tolerance components for measuring and control instruments.

- Machine tools – Supply of accessories and components for lathes, milling machines and CNC machining centres.

- Energy industry – Production of parts for turbines, plants and energy generation systems.

Innovation and Quality

ALGRA constantly invests in advanced production technologies, adopting automated manufacturing processes and latest-generation machinery.

- Advanced CAD/CAM systems – Design and digital simulation to guarantee precision and reduce production errors.

- Strict quality control – Each product is subjected to tests and dimensional checks to ensure high performance and maximum reliability.

- Automated production processes – Production with high-speed CNC machines to guarantee fast delivery times and competitive costs.

Global Presence and Services Offered

ALGRA exports its products all over the world, thanks to a network of international distributors and partners. The company also offers:

- Personalised technical advice – Support in choosing the product that best suits the customer's needs.

- Development of tailor-made solutions – Design and production of customised tool holders and accessories.

- After-sales service and technical support – Equipment maintenance, repair and optimisation services.

Conclusion

Choosing ALGRA means relying on a company with decades of experience in the field of precision mechanics and accessories for machine tools.

With a range of innovative products, a strong commitment to research and development and a production entirely Made in Italy, ALGRA continues to be a point of reference for companies looking for precision, reliability and quality in their mechanical machining.

Kintek: Leader in the Production of High Precision Tool Holders

Kintek is an Italian company founded in 1989 in Turin, specialising in the design, production and distribution of high quality tool holders for lathes and CNC machining centres. With over 35 years of experience, Kintek offers a complete range of solutions for machine tool tooling, guaranteeing precision, reliability and innovation.

Why choose Kintek products?

- Experience and Expertise: With more than three decades in the industry, Kintek combines tradition and innovation to provide cutting-edge products.

- Certified Quality: Kintek tool holders are manufactured according to DIN standards, ensuring high quality standards and international compliance.

- Wide Range of Products: With over 15,000 items in the catalogue, Kintek meets the various tooling requirements for lathes and machining centres.

- Continuous Innovation: The company constantly invests in research and development to offer technologically advanced solutions.

- Efficient Customer Service: Thanks to a well-stocked warehouse, Kintek is able to fulfil orders in just 24 hours, guaranteeing prompt service and customised support.

Kintek Product Range

1. Tool Holders for Turning

Designed to guarantee precision and durability in turning operations, they include:

- Static tool holders: Available with standard connections such as VDI (DIN 69880), BMT and Bolt-on, they ensure stable and precise tool fixing.

- Motorised tool holders: Ideal for complex operations, they offer versatility and high performance in CNC machining.

- Quick Clamping Systems: Solutions that allow for fast tool changes, reducing setup times and increasing production efficiency.

2. Milling Tool Holders

Kintek offers a wide range of tool holders for machining centres, including:

- Polygon Shanks (DIN 26623-1): Guarantee high rigidity and precision, ideal for multitasking machines.

- HSK-T Shanks (DIN 69893-T): Designed for high speed applications, they ensure excellent positioning precision.

- Keyless locking systems and hydraulic chucks: These offer tool clamping solutions with high holding force and ease of use.

3. Accessories and spare parts

To complete the offer, Kintek proposes:

- Reducing sleeves: These allow the adaptation of tools with different diameters, increasing the flexibility of machine tools.

- Extensions and Adapters: Solutions to extend the range of tools and adapt them to different applications.

- Presetting Systems: Tools for precise measurement and adjustment of tools, optimising production processes.

Industrial Applications

Kintek products are used in various industrial sectors, including:

- Mechanical Industry: Solutions for precision machining of metallic and non-metallic components.

- Aerospace Industry: Tools designed to meet the high standards of quality and precision required in the aeronautics industry.

- Automotive Industry: Tools for the production and maintenance of automotive components, guaranteeing efficiency and reliability.

- Mould Production: Specific tools for the production of moulds with high quality finishes and tight tolerances.

Conclusion

Choosing Kintek means relying on a partner with a long tradition of excellence in the production of high precision tool holders. With a constant commitment to innovation, quality and customer satisfaction, Kintek is the ideal choice for optimising production processes and guaranteeing excellent results in various industrial sectors.