Professional polishing felts: a complete guide for machine shops

In the world of machine shops, precision and quality of work are essential to guarantee excellent results and meet customer expectations. Among the essential tools for achieving perfectly smooth and shiny surfaces, professional polishing felts occupy a prominent place. These tools, often underestimated, are actually crucial to the finishing process, helping to improve the aesthetics and functionality of mechanical components.

What are professional polishing felts?

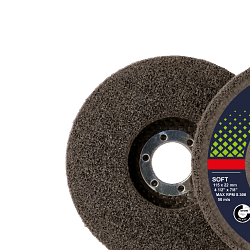

Professional polishing felts are discs or pads made of compressed wool or other fibrous materials, designed for use with polishing machines. Their main function is to apply abrasive or polishing compounds to metal, plastic or painted surfaces in order to remove imperfections, scratches and oxidation, and to achieve a glossy, uniform finish.

These felts are available in different densities and degrees of abrasiveness, allowing operators to choose the most suitable product for the specific requirements of the job at hand. Choosing the right felt depends on the type of material to be polished, the desired level of finish and the type of polishing compound used.

What are professional polishing felts used for?

Professional polishing felts are used in a wide range of industrial and craft applications. In machine shops, they are used for polishing automotive components, machine parts, tools and other metal objects. Their ability to remove scratches and surface imperfections makes them ideal for restoring damaged surfaces and preparing parts for painting or other surface treatments.

In addition to polishing metals, felts can be used on plastic and painted materials, making them versatile tools for a variety of industries, including automotive, aerospace, shipbuilding and furniture.

How are professional polishing felts used?

Using professional polishing felts requires some skill and attention to detail. Here is a step-by-step guide on how to use them effectively:

1. Preparing the surface: Before starting polishing, it is important to thoroughly clean the surface to be treated to remove dust, dirt and processing residues. This step is essential to prevent abrasive particles from damaging the surface during polishing.

2. Selection of felt and polishing compound: Select the felt and polishing compound best suited to the type of material and level of finish desired. Softer felts are ideal for final polishing, while harder felts are suitable for removing deep scratches.

3. Mounting the felt on the polisher: Attach the chosen felt to the polisher, ensuring that it is well centred and secure. Correct mounting is essential to avoid vibrations and ensure an even polish.

4. Application of polishing compound: Apply a small amount of polishing compound on the felt or directly on the surface to be polished. It is important not to overdo the amount of compound to avoid wastage and achieve an optimal finish.

5. Polishing: Start the polishing machine and begin working on the surface with slow, even movements. It is advisable to apply light, steady pressure to avoid damaging the surface. During polishing, it is important to constantly monitor the result and add polishing compound if necessary.

6. Final cleaning: Once polishing is complete, wipe the surface with a soft, lint-free cloth to remove any remaining polishing compound and achieve a flawless finish.

Advantages of professional polishing felts

The use of professional polishing felts offers numerous advantages, including:

- High-quality finish: The felts enable perfectly smooth and shiny surfaces, improving the aesthetics and functionality of mechanical components.

- Versatility: They can be used on a wide range of materials, making them indispensable tools in various industries.

- Efficiency: Thanks to their ability to quickly remove scratches and imperfections, felts reduce processing time and increase productivity.

- Durability: The high-quality felts are wear-resistant and can be used for numerous polishing cycles, offering excellent value for money.

Frequently asked questions about professional polishing felts

1. What is the difference between soft and hard felts?

Soft felts are ideal for final polishing and achieving a high-gloss finish, while hard felts are more suitable for removing deep scratches and surface imperfections.

2. Can I use polishing felts on painted surfaces?

Yes, felts can be used on painted surfaces, but it is important to choose the appropriate type of felt and polishing compound to avoid damaging the paint.

3. How can I extend the life of polishing felts?

To prolong the life of the felts, it is important to clean them regularly to remove polishing compound residues and abrasive particles. In addition, it is advisable to store them in a dry place protected from dust.

4. What are the risks associated with the use of polishing felts?

Improper use of polishing felts can cause damage to surfaces, such as scratches or burns. It is important to follow the manufacturer's instructions and use appropriate personal protective equipment to avoid injury.

5. Can polishing felts be used with manual machines?

Yes, polishing felts can be used with manual machines, but it is important to exercise precise control over pressure and movements to achieve a uniform finish.

In conclusion, professional polishing felts are essential tools for machine shops wishing to achieve high quality surfaces and improve the efficiency of their machining processes. With the right knowledge and attention to detail, these tools can transform the way surfaces are treated, delivering exceptional results and meeting the needs of the most demanding customers.

Read More Read Less