Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

Grinders and polishing equipment

Grinders and polishing equipment: an in-depth analysis for machine shops

In the world of machine shops, efficiency and precision are key elements in ensuring the quality of the work performed. Among the most essential tools for achieving these goals, grinders and polishing equipment occupy a prominent place. These tools not only improve the finish of products, but also help optimise production processes, reducing processing times and improving the overall quality of the final product.

Understanding grinders: types and applications

Grinders are versatile tools used for a variety of applications, including cutting, sanding and polishing different materials such as metal, wood and stone. There are different types of grinders, each designed for specific operational needs. Angle grinders, for example, are ideal for cutting and sanding work on flat surfaces and hard-to-reach corners. Bench grinders, on the other hand, are perfect for precision work on small components.

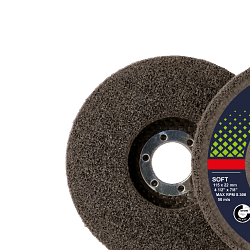

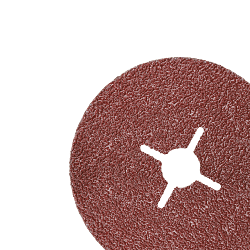

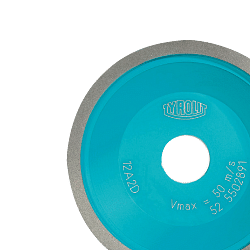

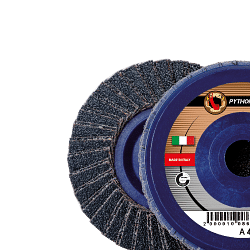

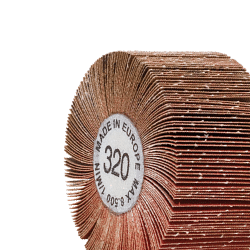

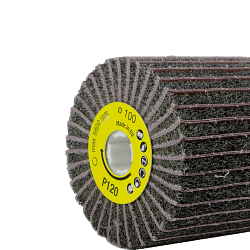

The correct use of grinders requires a thorough understanding of their technical characteristics. Choosing the right abrasive disc is crucial to achieving the desired results. Discs vary in terms of material, grit and size, and their selection depends on the type of work to be performed and the material to be processed. For example, for cutting hard metals, diamond discs should be used, while for polishing wood surfaces, aluminium oxide discs are more appropriate.

The importance of polishing equipment in workshops

Polishing equipment is equally crucial in machine shops, as it enables smooth and shiny surfaces, improving the aesthetics and functionality of products. Polishing is a process that requires precision and attention to detail, and the use of appropriate tools is essential to achieve optimal results.

Among the most common polishing tools are rotary and orbital polishers. Rotary polishers are ideal for jobs that require aggressive material removal, while orbital polishers are perfect for more delicate and uniform finishes. The choice between the two depends on the type of surface to be treated and the desired level of finish.

Advantages of using grinders and polishing equipment

The adoption of grinders and polishing equipment in machine shops offers numerous advantages. First of all, these tools significantly improve the quality of the final product, ensuring smooth and imperfection-free surfaces. In addition, the use of appropriate equipment reduces processing times, increasing production efficiency and reducing operating costs.

Another important advantage is the versatility offered by these tools. Grinders and polishers can be used on a wide range of materials, making them indispensable for workshops working with different types of products. In addition, the use of high-quality tools reduces the risk of errors and defects, enhancing the workshop's reputation and increasing customer satisfaction.

Frequently asked questions on the use of grinders and polishing equipment

1. What is the difference between an angle grinder and a bench grinder?

- The angle grinder is portable and ideal for work on flat surfaces and corners, while the bench grinder is stationary and used for precision work on small parts.

2. How to choose the right abrasive disc for a grinder?

- The choice of disc depends on the material to be processed and the type of work to be done. It is important to consider the disc material, grit and dimensions.

3. What are the advantages of orbital polishers over rotary polishers?

- Orbital polishers offer a smoother and more delicate finish, while rotary polishers are better suited for aggressive material removal.

4. Can grinders and polishers be used on different materials?

- Yes, these tools are versatile and can be used on a wide range of materials, including metal, wood and stone.

5. How can grinders and polishing equipment be kept in good condition?

- It is important to follow the manufacturer's instructions for maintenance, clean the tools regularly and replace worn discs and parts.

In conclusion, grinders and polishing equipment are indispensable tools for machine shops that aim to improve the quality and efficiency of their production processes. Understanding their technical characteristics and the correct use of these tools can make the difference between a mediocre job and a high quality product. Investing in quality equipment and properly training staff in the use of these tools is a fundamental step for any workshop that wishes to remain competitive in today's market.

Read More Read LessIn the world of machine shops, efficiency and precision are key elements in ensuring the quality of the work performed. Among the most essential tools for achieving these goals, grinders and polishing equipment occupy a prominent place. These tools not only improve the finish of products, but also help optimise production processes, reducing processing times and improving the overall quality of the final product.

Understanding grinders: types and applications

Grinders are versatile tools used for a variety of applications, including cutting, sanding and polishing different materials such as metal, wood and stone. There are different types of grinders, each designed for specific operational needs. Angle grinders, for example, are ideal for cutting and sanding work on flat surfaces and hard-to-reach corners. Bench grinders, on the other hand, are perfect for precision work on small components.

The correct use of grinders requires a thorough understanding of their technical characteristics. Choosing the right abrasive disc is crucial to achieving the desired results. Discs vary in terms of material, grit and size, and their selection depends on the type of work to be performed and the material to be processed. For example, for cutting hard metals, diamond discs should be used, while for polishing wood surfaces, aluminium oxide discs are more appropriate.

The importance of polishing equipment in workshops

Polishing equipment is equally crucial in machine shops, as it enables smooth and shiny surfaces, improving the aesthetics and functionality of products. Polishing is a process that requires precision and attention to detail, and the use of appropriate tools is essential to achieve optimal results.

Among the most common polishing tools are rotary and orbital polishers. Rotary polishers are ideal for jobs that require aggressive material removal, while orbital polishers are perfect for more delicate and uniform finishes. The choice between the two depends on the type of surface to be treated and the desired level of finish.

Advantages of using grinders and polishing equipment

The adoption of grinders and polishing equipment in machine shops offers numerous advantages. First of all, these tools significantly improve the quality of the final product, ensuring smooth and imperfection-free surfaces. In addition, the use of appropriate equipment reduces processing times, increasing production efficiency and reducing operating costs.

Another important advantage is the versatility offered by these tools. Grinders and polishers can be used on a wide range of materials, making them indispensable for workshops working with different types of products. In addition, the use of high-quality tools reduces the risk of errors and defects, enhancing the workshop's reputation and increasing customer satisfaction.

Frequently asked questions on the use of grinders and polishing equipment

1. What is the difference between an angle grinder and a bench grinder?

- The angle grinder is portable and ideal for work on flat surfaces and corners, while the bench grinder is stationary and used for precision work on small parts.

2. How to choose the right abrasive disc for a grinder?

- The choice of disc depends on the material to be processed and the type of work to be done. It is important to consider the disc material, grit and dimensions.

3. What are the advantages of orbital polishers over rotary polishers?

- Orbital polishers offer a smoother and more delicate finish, while rotary polishers are better suited for aggressive material removal.

4. Can grinders and polishers be used on different materials?

- Yes, these tools are versatile and can be used on a wide range of materials, including metal, wood and stone.

5. How can grinders and polishing equipment be kept in good condition?

- It is important to follow the manufacturer's instructions for maintenance, clean the tools regularly and replace worn discs and parts.

In conclusion, grinders and polishing equipment are indispensable tools for machine shops that aim to improve the quality and efficiency of their production processes. Understanding their technical characteristics and the correct use of these tools can make the difference between a mediocre job and a high quality product. Investing in quality equipment and properly training staff in the use of these tools is a fundamental step for any workshop that wishes to remain competitive in today's market.