Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

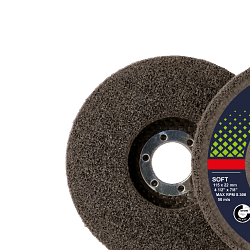

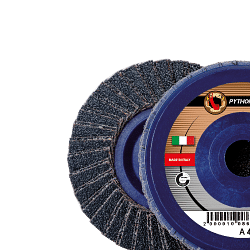

Flexible sanders

Professional flexible abrasives: innovation and precision for machine shops

In the world of machine shops, attention to detail and precision are key elements in guaranteeing the quality of the work performed. Professional flexible sanders are an indispensable tool for those working in this sector, offering advanced solutions for surface finishing. These tools, thanks to their versatility and precision, are able to meet the most complex requirements, improving efficiency and quality of work.

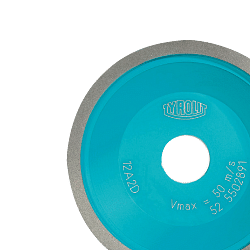

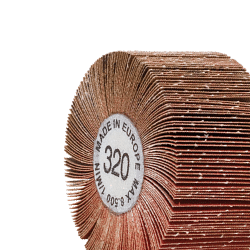

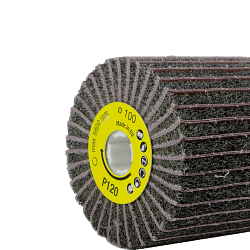

What are professional flexible sanders?

Professional flexible sanders are tools designed for sanding and finishing metal and other surfaces. Unlike conventional sanders, these devices are equipped with a flexible system that allows them to adapt to irregular and complex surfaces, ensuring a uniform, high-quality finish. Their structure generally consists of a motor body, a speed control system and a flexible holder that houses the abrasive material.

What are professional flexible sanders used for?

These tools are mainly used for finishing metal surfaces, but also find application on composite materials, wood and plastic. They are ideal for removing imperfections, burrs and oxidation, as well as preparing surfaces for subsequent treatments such as painting or chrome plating. Their ability to adapt to curved and uneven surfaces makes them particularly useful in industries such as automotive, aerospace and the production of precision mechanical components.

How are professional flexible sanders used?

The use of professional flexible sanders requires a certain amount of technical expertise to ensure optimal results. Before starting, it is essential to select the most suitable abrasive material for the type of surface to be treated and the desired degree of finish. Next, the abrasive material is mounted on the sander's flexible backing. During the sanding operation, it is important to maintain constant and even pressure on the surface, adjusting the speed of the sander according to the material and type of finish required.

Benefits of using professional flexible sanders

The adoption of professional flexible sanders in machine shops offers several advantages. Firstly, their ability to adapt to complex surfaces reduces the risk of damage and improves the quality of the finish. Furthermore, the ability to adjust speed and pressure allows the sanding process to be optimised, reducing machining time and increasing production efficiency. These tools are also designed to reduce vibration and noise, improving operator comfort and reducing fatigue during prolonged use.

Frequently asked questions about professional flexible sanders

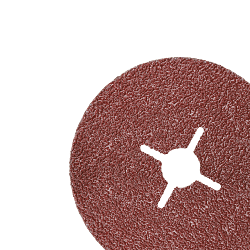

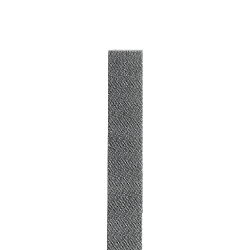

1. What are the most common abrasive materials used with flexible sanders?

The most common abrasive materials include sandpaper, silicon carbide discs and aluminium oxide belts. The choice of material depends on the type of surface to be treated and the desired degree of finish.

2. Can flexible sanders be used on painted surfaces?

Yes, flexible sanders can be used on painted surfaces to remove imperfections or prepare the surface for a new paint job. However, it is important to select a suitable abrasive material to avoid damaging the existing paint.

3. What precautions should be taken when using flexible sanders?

It is essential to wear personal protective equipment such as safety goggles and dust masks. It is also important to follow the manufacturer's instructions to ensure safe and effective use of the tool.

4. Are flexible sanders suitable for use on composite materials?

Yes, flexible sanders are ideal for working on composite materials due to their ability to adapt to uneven surfaces and the ability to adjust speed and pressure.

5. How do I maintain flexible sanders?

Maintenance of flexible sanders includes regular cleaning of the device, replacement of worn abrasive materials and periodic inspection of mechanical parts to ensure optimal operation.

In conclusion, professional flexible sanders are a valuable resource for machine shops, offering advanced surface finishing solutions. Their versatility, precision and ability to adapt to complex surfaces make them indispensable tools for those seeking to improve the quality and efficiency of their work. Investing in these devices means not only improving the quality of machining, but also optimising production processes, reducing machining times and increasing customer satisfaction.

Read More Read LessIn the world of machine shops, attention to detail and precision are key elements in guaranteeing the quality of the work performed. Professional flexible sanders are an indispensable tool for those working in this sector, offering advanced solutions for surface finishing. These tools, thanks to their versatility and precision, are able to meet the most complex requirements, improving efficiency and quality of work.

What are professional flexible sanders?

Professional flexible sanders are tools designed for sanding and finishing metal and other surfaces. Unlike conventional sanders, these devices are equipped with a flexible system that allows them to adapt to irregular and complex surfaces, ensuring a uniform, high-quality finish. Their structure generally consists of a motor body, a speed control system and a flexible holder that houses the abrasive material.

What are professional flexible sanders used for?

These tools are mainly used for finishing metal surfaces, but also find application on composite materials, wood and plastic. They are ideal for removing imperfections, burrs and oxidation, as well as preparing surfaces for subsequent treatments such as painting or chrome plating. Their ability to adapt to curved and uneven surfaces makes them particularly useful in industries such as automotive, aerospace and the production of precision mechanical components.

How are professional flexible sanders used?

The use of professional flexible sanders requires a certain amount of technical expertise to ensure optimal results. Before starting, it is essential to select the most suitable abrasive material for the type of surface to be treated and the desired degree of finish. Next, the abrasive material is mounted on the sander's flexible backing. During the sanding operation, it is important to maintain constant and even pressure on the surface, adjusting the speed of the sander according to the material and type of finish required.

Benefits of using professional flexible sanders

The adoption of professional flexible sanders in machine shops offers several advantages. Firstly, their ability to adapt to complex surfaces reduces the risk of damage and improves the quality of the finish. Furthermore, the ability to adjust speed and pressure allows the sanding process to be optimised, reducing machining time and increasing production efficiency. These tools are also designed to reduce vibration and noise, improving operator comfort and reducing fatigue during prolonged use.

Frequently asked questions about professional flexible sanders

1. What are the most common abrasive materials used with flexible sanders?

The most common abrasive materials include sandpaper, silicon carbide discs and aluminium oxide belts. The choice of material depends on the type of surface to be treated and the desired degree of finish.

2. Can flexible sanders be used on painted surfaces?

Yes, flexible sanders can be used on painted surfaces to remove imperfections or prepare the surface for a new paint job. However, it is important to select a suitable abrasive material to avoid damaging the existing paint.

3. What precautions should be taken when using flexible sanders?

It is essential to wear personal protective equipment such as safety goggles and dust masks. It is also important to follow the manufacturer's instructions to ensure safe and effective use of the tool.

4. Are flexible sanders suitable for use on composite materials?

Yes, flexible sanders are ideal for working on composite materials due to their ability to adapt to uneven surfaces and the ability to adjust speed and pressure.

5. How do I maintain flexible sanders?

Maintenance of flexible sanders includes regular cleaning of the device, replacement of worn abrasive materials and periodic inspection of mechanical parts to ensure optimal operation.

In conclusion, professional flexible sanders are a valuable resource for machine shops, offering advanced surface finishing solutions. Their versatility, precision and ability to adapt to complex surfaces make them indispensable tools for those seeking to improve the quality and efficiency of their work. Investing in these devices means not only improving the quality of machining, but also optimising production processes, reducing machining times and increasing customer satisfaction.