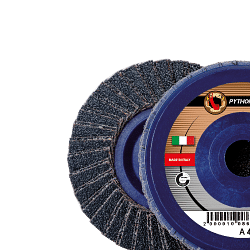

< Abrasives Flap discs

Flap discs for grinding are an essential component in machine shops, where precision and quality of work are paramount. Although these tools may seem simple, they contain a technical complexity that makes them indispensable for a wide range of industrial applications. In this in-depth look, we will explore in detail what flap discs are, how they are used, their advantages and answer the most frequent questions that arise in the context of machining.

Understanding flap discs for grinding

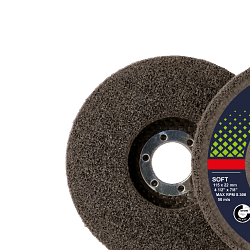

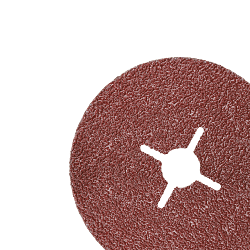

Flap discs are abrasive tools consisting of a series of overlapping flaps, usually made of abrasive material such as aluminium oxide or silicon carbide. These flaps are arranged in a fan shape around a central backing, usually made of fibreglass or reinforced plastic, which gives the disc a strong and durable structure. The flap design allows for a larger contact surface area than conventional abrasive discs, improving the efficiency of the grinding process.

Applications and use in machine shops

Flap discs are mainly used for grinding, honing and finishing operations on a variety of materials, including metals, alloys, wood and plastics. In machine shops, these discs are used to remove burrs, burrs, oxidation and to prepare surfaces for painting or other surface treatments. Their versatility makes them suitable for both coarse machining and precision finishing.

Advantages of flap discs compared to other abrasive tools

One of the main advantages of flap discs is their ability to adapt to irregular surfaces, ensuring a uniform finish and reducing the risk of damaging the material being processed. In addition, the flap arrangement allows for more effective heat dissipation, preventing overheating and prolonging the life of the disc. Compared to conventional abrasive discs, flap discs offer a longer service life and a reduction in machining time due to their ability to remove material more quickly and efficiently.

Selecting the right flap disc for your application

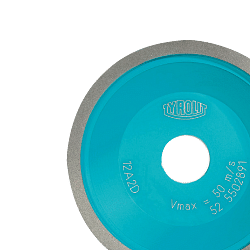

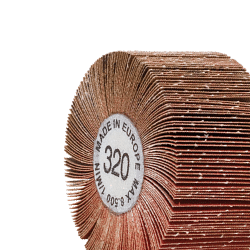

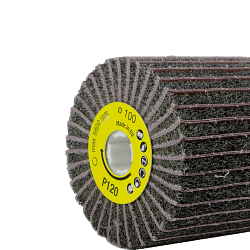

The choice of the most suitable flap disc depends on several factors, including the type of material to be processed, the desired finish and the technical specifications of the grinder being used. It is important to consider the abrasive grain, which determines the cutting capacity and the quality of the finish. Coarser grains are ideal for quick material removal, while finer grains are preferable for precision finishes. In addition, the size and shape of the disc must be compatible with the equipment available in the workshop.

Maintenance and safety when using flap discs

To ensure optimal performance and safety during use, it is essential to follow certain maintenance guidelines. Flap discs must be stored in a dry environment and protected from shocks and falls. Before use, it is important to inspect the disc for damage or excessive wear. During operation, it is essential to wear personal protective equipment, such as safety goggles and gloves, to prevent injury from chips or abrasive dust.

Frequently asked questions about flap discs

1. What is the difference between a flap disc and a conventional abrasive disc?

Flap discs offer a larger contact surface and better heat dissipation, resulting in a smoother finish and a longer lifetime than conventional abrasive discs.

2. Can I use flap discs on non-metallic materials?

Yes, flap discs are suitable for a variety of materials, including wood and plastic, as well as metals.

3. How can I extend the service life of my flap disc?

Storing your discs in a dry environment, inspecting them regularly for damage and using the right pressure when grinding can help extend their service life.

4. What are the risks associated with using flap discs?

The main risks include injury from chips or abrasive dust. It is important to wear protective equipment and follow safety guidelines.

5. How do I choose the right abrasive grain for my application?

The choice of grit depends on the type of work: coarse grits for quick material removal, fine grits for precision finishing.

In conclusion, flap discs for grinding are versatile and highly effective tools in machine shops. Their ability to adapt to different surfaces and materials, combined with increased durability and efficiency, makes them a preferred choice for many industrial applications. With proper selection, maintenance and use, flap discs can significantly improve the quality and productivity of grinding operations.

Read More Read Less