Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

Files and rasps

Professional files and rasps: essential tools for machine shops

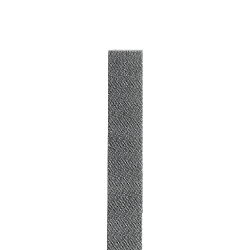

In the world of machine shops, attention to detail is essential to ensure the quality and precision of the work performed. Among the tools that play a crucial role in this context, professional files and rasps stand out for their versatility and ability to finish surfaces with millimetre precision. These tools, often underestimated, are actually fundamental pillars for anyone working in mechanical engineering, metalworking and industrial maintenance.

Files and rasps: a technical overview

Files and rasps are hand tools used to shape, finish and smooth materials such as metal, wood and plastic. The main difference between the two lies in the structure of the abrasive surface: files have a surface with finer, closely spaced teeth, while rasps have larger, more widely spaced teeth, ideal for removing material more aggressively.

Files come in different shapes and sizes, including flat, round, semi-circular and triangular, each designed for specific applications. Rasps, on the other hand, are often used for coarser work, such as roughing irregular surfaces or removing large amounts of material.

Practical applications in machine shops

In machine shops, files and rasps are used in a wide range of applications. They are essential for finishing metal components, removing burrs and preparing surfaces for further processing. For example, during the construction of an engine, files can be used to fit components perfectly, ensuring a precise fit and minimising wear.

Rasps, on the other hand, are often used in woodworking and sculpture, but also find application in metalworking, especially when excess material needs to be quickly removed or complex surfaces need to be modelled.

Advantages of using professional files and rasps

The use of professional files and rasps offers numerous advantages, including the ability to achieve high quality finishes and the ability to work precisely on complex details. These tools allow machining operations that would be difficult or impossible to carry out with automatic machines, especially when it comes to one-off pieces or prototypes.

Furthermore, professional files and rasps are designed to last, thanks to the use of high quality materials and advanced manufacturing techniques. This translates into a long-term investment for machine shops, which can count on reliable, high-performance tools for years to come.

Frequently asked questions about the use of files and rasps

One of the most common questions concerns the maintenance of these tools. It is essential to keep files and rasps clean and well maintained to preserve their effectiveness. After each use, it is advisable to remove residual material with a wire brush and store the tools in a dry environment to prevent corrosion.

Another frequently asked question concerns the choice between files and rasps. The decision depends on the type of material to be worked on and the level of precision required. For finishing work on metals, files are generally preferred, while rasps are ideal for roughing and working on wood.

Conclusion: the importance of choosing quality tools

In conclusion, professional files and rasps are indispensable tools for machine shops, offering precision, versatility and durability. Investing in high-quality tools not only improves the quality of work, but also increases operational efficiency, reducing processing time and improving customer satisfaction. For those working in the mechanical engineering sector, understanding the importance of these tools and knowing how to use them well is a fundamental step towards professional excellence.

Read More Read LessIn the world of machine shops, attention to detail is essential to ensure the quality and precision of the work performed. Among the tools that play a crucial role in this context, professional files and rasps stand out for their versatility and ability to finish surfaces with millimetre precision. These tools, often underestimated, are actually fundamental pillars for anyone working in mechanical engineering, metalworking and industrial maintenance.

Files and rasps: a technical overview

Files and rasps are hand tools used to shape, finish and smooth materials such as metal, wood and plastic. The main difference between the two lies in the structure of the abrasive surface: files have a surface with finer, closely spaced teeth, while rasps have larger, more widely spaced teeth, ideal for removing material more aggressively.

Files come in different shapes and sizes, including flat, round, semi-circular and triangular, each designed for specific applications. Rasps, on the other hand, are often used for coarser work, such as roughing irregular surfaces or removing large amounts of material.

Practical applications in machine shops

In machine shops, files and rasps are used in a wide range of applications. They are essential for finishing metal components, removing burrs and preparing surfaces for further processing. For example, during the construction of an engine, files can be used to fit components perfectly, ensuring a precise fit and minimising wear.

Rasps, on the other hand, are often used in woodworking and sculpture, but also find application in metalworking, especially when excess material needs to be quickly removed or complex surfaces need to be modelled.

Advantages of using professional files and rasps

The use of professional files and rasps offers numerous advantages, including the ability to achieve high quality finishes and the ability to work precisely on complex details. These tools allow machining operations that would be difficult or impossible to carry out with automatic machines, especially when it comes to one-off pieces or prototypes.

Furthermore, professional files and rasps are designed to last, thanks to the use of high quality materials and advanced manufacturing techniques. This translates into a long-term investment for machine shops, which can count on reliable, high-performance tools for years to come.

Frequently asked questions about the use of files and rasps

One of the most common questions concerns the maintenance of these tools. It is essential to keep files and rasps clean and well maintained to preserve their effectiveness. After each use, it is advisable to remove residual material with a wire brush and store the tools in a dry environment to prevent corrosion.

Another frequently asked question concerns the choice between files and rasps. The decision depends on the type of material to be worked on and the level of precision required. For finishing work on metals, files are generally preferred, while rasps are ideal for roughing and working on wood.

Conclusion: the importance of choosing quality tools

In conclusion, professional files and rasps are indispensable tools for machine shops, offering precision, versatility and durability. Investing in high-quality tools not only improves the quality of work, but also increases operational efficiency, reducing processing time and improving customer satisfaction. For those working in the mechanical engineering sector, understanding the importance of these tools and knowing how to use them well is a fundamental step towards professional excellence.