Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

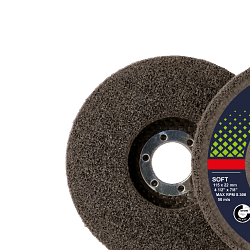

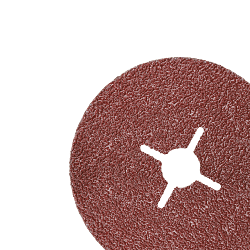

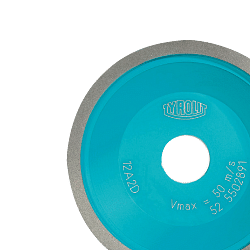

Fabric discs for surface treatment

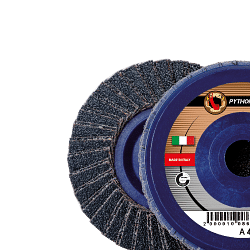

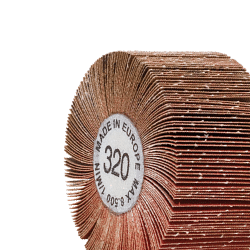

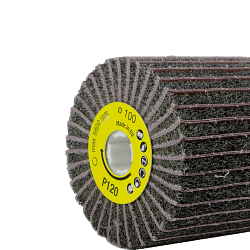

Fabric abrasive discs for surface treatment are an essential component of modern machine shops. Although these tools may seem simple at first glance, they contain a technical complexity that makes them indispensable for a wide range of industrial applications. In this in-depth look, we will explore in detail what fabric discs are, what they are used for, how they are used, the advantages they offer and answer some of the most frequently asked questions on this topic.

Understanding fabric discs for surface treatment

Cloth discs are abrasive tools designed for surface treatment. They consist of layers of fabric impregnated with abrasive materials, such as aluminium oxide or silicon carbide, which give them the ability to remove material from machined surfaces. These discs are available in different grits, which determine the level of finish they can achieve, and are used in combination with rotary machine tools.

Main applications of fabric discs

The applications of cloth discs are many and vary depending on the specific needs of machine shops. Among the main ones are rust and paint removal, cleaning metal surfaces, preparing surfaces for painting and final polishing. Due to their versatility, cloth discs are used in sectors ranging from automotive to aerospace to industrial machinery manufacturing.

How to use fabric discs correctly

The correct use of fabric discs is crucial for optimal results and operator safety. Before starting, it is important to select the disc with the appropriate grit for the specific application. A coarser grit is ideal for removing heavy material, while a finer grit is suitable for finishing. During use, it is essential to maintain constant and even pressure on the surface, avoiding tilting the disc, to prevent damage to both the disc and the workpiece.

Advantages of fabric discs in surface treatment

Cloth discs offer several advantages over other abrasive tools. Firstly, their flexibility allows them to easily adapt to uneven surfaces, ensuring a uniform finish. In addition, the fabric structure allows for more effective heat dissipation, reducing the risk of overheating and deformation of the material being processed. Finally, the lifetime of cloth discs is generally longer than that of other types of abrasive discs due to their ability to self-sharpen during use.

Frequently asked questions about cloth discs

1. What is the difference between cloth and paper discs?

Cloth discs are more flexible and resistant than paper discs, making them ideal for applications requiring greater adaptability and durability.

2. Can I use fabric discs on non-metallic materials?

Yes, fabric discs can be used on a variety of materials, including wood and plastic, provided you choose the appropriate grit.

3. How can I prolong the life of my fabric discs?

To prolong the life of your fabric discs, it is important to use them at the correct speed, avoid excessive pressure and clean them regularly to remove accumulated residue.

4. What are the signs that a fabric disc needs to be replaced?

Signs that indicate that a fabric disc needs to be replaced include a reduction in abrasive effectiveness, visible tears or damage, and an increase in temperature during use.

Conclusions

Fabric discs for surface treatment are indispensable tools in machine shops due to their versatility, efficiency and durability. Understanding their characteristics, applications and correct usage techniques is crucial to fully utilise their benefits and ensure high quality results. With proper maintenance and careful selection, fabric discs can significantly improve surface machining processes, contributing to the success of industrial operations.

Read More Read LessUnderstanding fabric discs for surface treatment

Cloth discs are abrasive tools designed for surface treatment. They consist of layers of fabric impregnated with abrasive materials, such as aluminium oxide or silicon carbide, which give them the ability to remove material from machined surfaces. These discs are available in different grits, which determine the level of finish they can achieve, and are used in combination with rotary machine tools.

Main applications of fabric discs

The applications of cloth discs are many and vary depending on the specific needs of machine shops. Among the main ones are rust and paint removal, cleaning metal surfaces, preparing surfaces for painting and final polishing. Due to their versatility, cloth discs are used in sectors ranging from automotive to aerospace to industrial machinery manufacturing.

How to use fabric discs correctly

The correct use of fabric discs is crucial for optimal results and operator safety. Before starting, it is important to select the disc with the appropriate grit for the specific application. A coarser grit is ideal for removing heavy material, while a finer grit is suitable for finishing. During use, it is essential to maintain constant and even pressure on the surface, avoiding tilting the disc, to prevent damage to both the disc and the workpiece.

Advantages of fabric discs in surface treatment

Cloth discs offer several advantages over other abrasive tools. Firstly, their flexibility allows them to easily adapt to uneven surfaces, ensuring a uniform finish. In addition, the fabric structure allows for more effective heat dissipation, reducing the risk of overheating and deformation of the material being processed. Finally, the lifetime of cloth discs is generally longer than that of other types of abrasive discs due to their ability to self-sharpen during use.

Frequently asked questions about cloth discs

1. What is the difference between cloth and paper discs?

Cloth discs are more flexible and resistant than paper discs, making them ideal for applications requiring greater adaptability and durability.

2. Can I use fabric discs on non-metallic materials?

Yes, fabric discs can be used on a variety of materials, including wood and plastic, provided you choose the appropriate grit.

3. How can I prolong the life of my fabric discs?

To prolong the life of your fabric discs, it is important to use them at the correct speed, avoid excessive pressure and clean them regularly to remove accumulated residue.

4. What are the signs that a fabric disc needs to be replaced?

Signs that indicate that a fabric disc needs to be replaced include a reduction in abrasive effectiveness, visible tears or damage, and an increase in temperature during use.

Conclusions

Fabric discs for surface treatment are indispensable tools in machine shops due to their versatility, efficiency and durability. Understanding their characteristics, applications and correct usage techniques is crucial to fully utilise their benefits and ensure high quality results. With proper maintenance and careful selection, fabric discs can significantly improve surface machining processes, contributing to the success of industrial operations.