Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

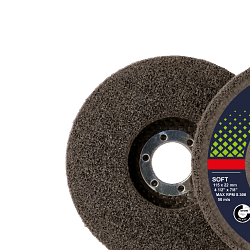

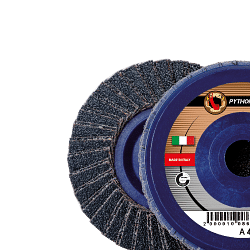

Deburring grinding wheel

Professional deburring wheels are a crucial element in modern machine shops. Although they may seem simple at first glance, these tools are the result of continuous innovation and advanced technical research, designed to meet the specific precision and efficiency requirements of the industry. In this in-depth look, we will explore in detail what professional deburring wheels are, how they are used, the benefits they offer, and answer some of the most frequently asked questions in the industry.

Understanding Professional Deburring Wheels

Deburring wheels are abrasive tools used to remove burrs, i.e. the irregularities or material residues that form on the edges of machined workpieces. These burrs can be the result of cutting, milling or drilling processes and, if not removed, can compromise the quality of the final product, negatively affecting assembly and aesthetics. Professional deburring wheels are designed to ensure a smooth and uniform finish, thus improving the overall quality of the product.

The importance of deburring wheels in industry

In the context of machine shops, the use of professional deburring wheels is essential to ensure that the components produced are free of defects and ready for assembly or sale. These tools not only improve the aesthetics of machined parts, but also help reduce the risk of injuries caused by sharp edges. In addition, the use of high-quality grinding wheels can increase the life of components, reducing the need for frequent repairs or replacements.

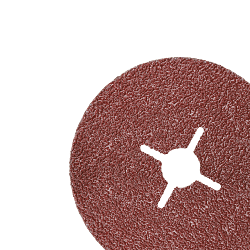

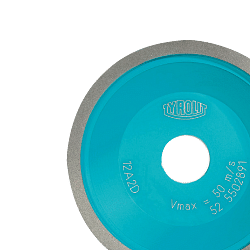

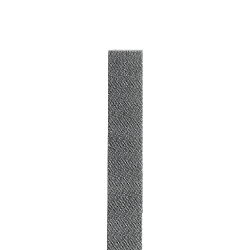

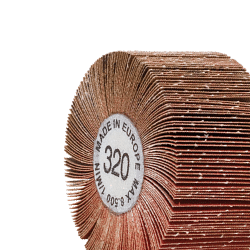

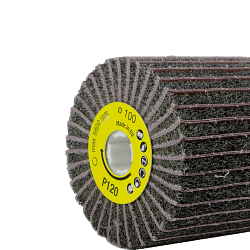

How to choose the right deburring wheel

Choosing the right deburring wheel depends on several factors, including the type of material to be machined, the size of the workpiece and the desired level of finish. Grinding wheels are available in a variety of grits and materials, each designed for specific applications. For example, silicon carbide wheels are ideal for hard materials such as metal, while aluminium oxide wheels are more suitable for softer materials such as plastic.

Advantages of professional deburring wheels

The use of professional deburring wheels offers numerous advantages. First of all, they improve the efficiency of the production process, reducing the time needed to finish workpieces. Furthermore, they guarantee consistent quality, reducing the risk of defects and improving customer satisfaction. High quality grinding wheels are also more durable, reducing replacement and maintenance costs.

Frequently asked questions about deburring wheels

1. What is the difference between a deburring wheel and a grinding wheel?

Deburring wheels are specifically designed to remove burrs and ensure a smooth finish, whereas grinding wheels are used to remove excess material and shape parts.

2. How is a deburring wheel maintained?

It is important to clean the grinding wheel regularly to remove material residue and to check wear to ensure optimum performance. It is also advisable to follow the manufacturer's instructions for maintenance and replacement.

3. Can deburring wheels be used on all materials?

No, it is important to choose the right grinding wheel for the specific material to be machined. Using an unsuitable grinding wheel may damage the workpiece or reduce the deburring effectiveness.

Conclusion

Professional deburring wheels are indispensable tools in machine shops, helping to improve the quality and efficiency of production. Choosing the right grinding wheel and maintaining it correctly can make the difference between a high quality product and a defective one. With continued innovation in the industry, deburring wheels will continue to evolve, offering ever more advanced solutions to industry needs.

Read More Read LessUnderstanding Professional Deburring Wheels

Deburring wheels are abrasive tools used to remove burrs, i.e. the irregularities or material residues that form on the edges of machined workpieces. These burrs can be the result of cutting, milling or drilling processes and, if not removed, can compromise the quality of the final product, negatively affecting assembly and aesthetics. Professional deburring wheels are designed to ensure a smooth and uniform finish, thus improving the overall quality of the product.

The importance of deburring wheels in industry

In the context of machine shops, the use of professional deburring wheels is essential to ensure that the components produced are free of defects and ready for assembly or sale. These tools not only improve the aesthetics of machined parts, but also help reduce the risk of injuries caused by sharp edges. In addition, the use of high-quality grinding wheels can increase the life of components, reducing the need for frequent repairs or replacements.

How to choose the right deburring wheel

Choosing the right deburring wheel depends on several factors, including the type of material to be machined, the size of the workpiece and the desired level of finish. Grinding wheels are available in a variety of grits and materials, each designed for specific applications. For example, silicon carbide wheels are ideal for hard materials such as metal, while aluminium oxide wheels are more suitable for softer materials such as plastic.

Advantages of professional deburring wheels

The use of professional deburring wheels offers numerous advantages. First of all, they improve the efficiency of the production process, reducing the time needed to finish workpieces. Furthermore, they guarantee consistent quality, reducing the risk of defects and improving customer satisfaction. High quality grinding wheels are also more durable, reducing replacement and maintenance costs.

Frequently asked questions about deburring wheels

1. What is the difference between a deburring wheel and a grinding wheel?

Deburring wheels are specifically designed to remove burrs and ensure a smooth finish, whereas grinding wheels are used to remove excess material and shape parts.

2. How is a deburring wheel maintained?

It is important to clean the grinding wheel regularly to remove material residue and to check wear to ensure optimum performance. It is also advisable to follow the manufacturer's instructions for maintenance and replacement.

3. Can deburring wheels be used on all materials?

No, it is important to choose the right grinding wheel for the specific material to be machined. Using an unsuitable grinding wheel may damage the workpiece or reduce the deburring effectiveness.

Conclusion

Professional deburring wheels are indispensable tools in machine shops, helping to improve the quality and efficiency of production. Choosing the right grinding wheel and maintaining it correctly can make the difference between a high quality product and a defective one. With continued innovation in the industry, deburring wheels will continue to evolve, offering ever more advanced solutions to industry needs.