Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

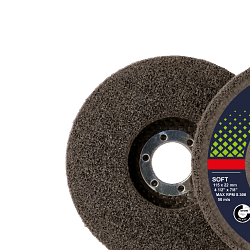

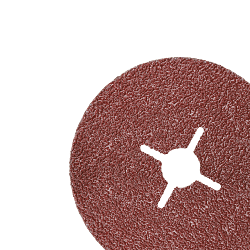

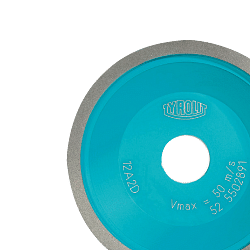

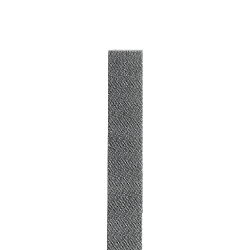

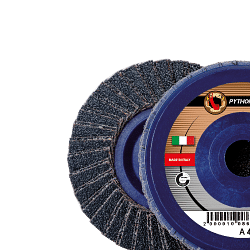

Abrasive wheels for buffing machines

Abrasives for professional satin finishers are an essential element in the machine shop sector, where precision and quality surface finishes are paramount. These tools, designed to ensure a uniform, high quality finish, are essential for anyone working in the field of metal and surface machining. In this in-depth look, we will explore in detail what abrasive rollers are, how they are used, the advantages they offer and answer some of the most frequently asked questions on this topic.

Understanding abrasive rollers for satin finishers

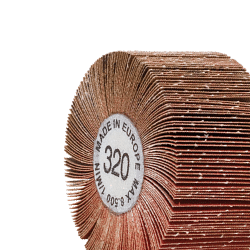

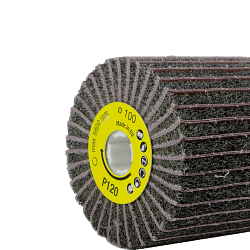

Abrasive rollers are cylindrical components coated with abrasive materials, designed to be mounted on satin finishing machines. These tools are used for the surface finishing of metals, alloys and other materials, imparting a satin texture that enhances the aesthetics and functionality of the final product. Satin finishing is a process that removes surface imperfections, creating a smooth and uniform finish.

Applications and use of abrasive rollers

Professional satin finishers, equipped with abrasive rollers, find application in a wide range of industries. From the automotive to the aerospace industry, via the production of household appliances and furniture, the need for perfectly finished surfaces is universal. Abrasive rollers are particularly appreciated for their ability to work on curved and uneven surfaces, where other tools may not be effective.

The use of abrasive rollers requires a thorough knowledge of satin finishing techniques. It is essential to select the most suitable type of abrasive for the material to be worked on, as well as to adjust the speed and pressure of the satinisher to achieve the desired results. Choosing the right roller can significantly influence the quality of the finish, making a detailed understanding of the technical specifications of each product essential.

Advantages of abrasive rollers for satin finishers

One of the main advantages of abrasive rollers is their ability to produce high-quality finishes efficiently. Compared to other finishing methods, abrasive rollers offer greater uniformity and control over the end result. This is especially important in sectors where precision is crucial, such as in the production of precision mechanical components.

Furthermore, abrasive rollers are known for their durability and resistance to wear. The quality of the abrasive materials used in their production guarantees a long service life, reducing the need for frequent replacement and lowering overall operating costs. This makes them an economical and sustainable choice for machine shops looking to optimise their production processes.

Frequently asked questions about abrasive rollers

1. What materials can be processed with abrasive rollers?

Abrasive rollers are versatile and can be used on a wide range of materials, including stainless steel, aluminium, brass and plastic. Choosing the right roller depends on the specific material and the type of finish desired.

2. How do I choose the right abrasive roller?

The choice of abrasive roller depends on several factors, including the type of material to be processed, the grit of the abrasive and the type of finish desired. It is important to consult the manufacturer's technical specifications and seek expert advice if necessary.

3. What maintenance is required for abrasive rollers?

The maintenance of abrasive rollers is relatively simple. It is important to clean the rollers regularly to remove material residue and to check the abrasive wear. Proper maintenance prolongs the life of the roller and ensures high quality results.

4. What are the differences between the various types of abrasive rollers?

There are different types of abrasive rollers, each designed for specific applications. Coarse grit rollers are ideal for material removal and surface preparation, while fine grit rollers are used for finishing and polishing. Choosing the right roller depends on the specific application and the desired result.

5. Can abrasive rollers be used on painted surfaces?

Yes, abrasive rollers can be used on painted surfaces, but it is important to select the right roller to avoid damaging the paint. Fine-grit rollers are generally recommended for working on painted surfaces, as they offer more control and reduce the risk of scratches.

Conclusion

Abrasive rollers for professional satin finishers are indispensable tools for machine shops looking to achieve high-quality finishes on a variety of materials. Their versatility, durability and ability to produce consistent results make them an excellent choice for a wide range of industrial applications. Understanding the technical specifications and best practices for using abrasive rollers is critical to maximising the benefits of these tools and ensuring optimal results in every project.

Read More Read LessUnderstanding abrasive rollers for satin finishers

Abrasive rollers are cylindrical components coated with abrasive materials, designed to be mounted on satin finishing machines. These tools are used for the surface finishing of metals, alloys and other materials, imparting a satin texture that enhances the aesthetics and functionality of the final product. Satin finishing is a process that removes surface imperfections, creating a smooth and uniform finish.

Applications and use of abrasive rollers

Professional satin finishers, equipped with abrasive rollers, find application in a wide range of industries. From the automotive to the aerospace industry, via the production of household appliances and furniture, the need for perfectly finished surfaces is universal. Abrasive rollers are particularly appreciated for their ability to work on curved and uneven surfaces, where other tools may not be effective.

The use of abrasive rollers requires a thorough knowledge of satin finishing techniques. It is essential to select the most suitable type of abrasive for the material to be worked on, as well as to adjust the speed and pressure of the satinisher to achieve the desired results. Choosing the right roller can significantly influence the quality of the finish, making a detailed understanding of the technical specifications of each product essential.

Advantages of abrasive rollers for satin finishers

One of the main advantages of abrasive rollers is their ability to produce high-quality finishes efficiently. Compared to other finishing methods, abrasive rollers offer greater uniformity and control over the end result. This is especially important in sectors where precision is crucial, such as in the production of precision mechanical components.

Furthermore, abrasive rollers are known for their durability and resistance to wear. The quality of the abrasive materials used in their production guarantees a long service life, reducing the need for frequent replacement and lowering overall operating costs. This makes them an economical and sustainable choice for machine shops looking to optimise their production processes.

Frequently asked questions about abrasive rollers

1. What materials can be processed with abrasive rollers?

Abrasive rollers are versatile and can be used on a wide range of materials, including stainless steel, aluminium, brass and plastic. Choosing the right roller depends on the specific material and the type of finish desired.

2. How do I choose the right abrasive roller?

The choice of abrasive roller depends on several factors, including the type of material to be processed, the grit of the abrasive and the type of finish desired. It is important to consult the manufacturer's technical specifications and seek expert advice if necessary.

3. What maintenance is required for abrasive rollers?

The maintenance of abrasive rollers is relatively simple. It is important to clean the rollers regularly to remove material residue and to check the abrasive wear. Proper maintenance prolongs the life of the roller and ensures high quality results.

4. What are the differences between the various types of abrasive rollers?

There are different types of abrasive rollers, each designed for specific applications. Coarse grit rollers are ideal for material removal and surface preparation, while fine grit rollers are used for finishing and polishing. Choosing the right roller depends on the specific application and the desired result.

5. Can abrasive rollers be used on painted surfaces?

Yes, abrasive rollers can be used on painted surfaces, but it is important to select the right roller to avoid damaging the paint. Fine-grit rollers are generally recommended for working on painted surfaces, as they offer more control and reduce the risk of scratches.

Conclusion

Abrasive rollers for professional satin finishers are indispensable tools for machine shops looking to achieve high-quality finishes on a variety of materials. Their versatility, durability and ability to produce consistent results make them an excellent choice for a wide range of industrial applications. Understanding the technical specifications and best practices for using abrasive rollers is critical to maximising the benefits of these tools and ensuring optimal results in every project.