Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

Abrasive brushes

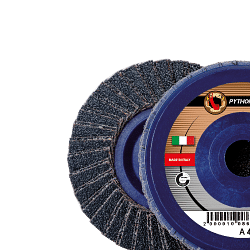

Professional abrasive brushes are an essential tool for machine shops and the manufacturing industry in general. Although these tools may seem simple at first sight, they are the result of continuous technological innovation and a deep understanding of the specific needs of the industry. Abrasive brushes are designed to offer an effective and versatile solution for a wide range of applications, from surface finishing to the removal of unwanted materials.

Understanding Professional Abrasive Brushes

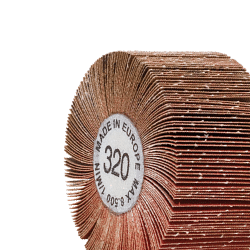

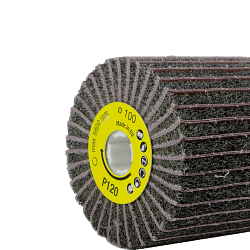

Abrasive brushes consist of a backing, usually metal or plastic, onto which abrasive bristles are attached. These bristles can be made of different materials, including silicon carbide, aluminium oxide or ceramic, depending on the specific application. The choice of abrasive material is crucial, as it determines the brush's ability to remove material and the finish it can achieve.

Applications of Abrasive Brushes

Abrasive brushes are used in numerous industrial applications. They are used for cleaning surfaces, removing burrs, preparing surfaces for painting, and finishing metal components. Their ability to adapt to uneven surfaces makes them particularly useful in contexts where precision is paramount.

Advantages of Professional Abrasive Brushes

One of the main advantages of abrasive brushes is their versatility. They can be used on a wide range of materials, including metals, wood and plastic. In addition, they offer precise control over the amount of material removed, reducing the risk of damage to the workpiece. Abrasive brushes are also known for their durability and resistance to wear, making them a worthwhile investment for machine shops.

Correct use of abrasive brushes

To achieve the best results, it is essential to use the abrasive brushes correctly. This includes choosing the right brush for the specific application, setting the appropriate rotation speed and applying the right pressure. Improper use can lead to unsatisfactory results and premature brush wear.

Frequently asked questions about abrasive brushes

One of the most common questions concerns the durability of abrasive brushes. Durability depends on several factors, including the material of the brush, the application and the conditions of use. In general, high-quality abrasive brushes can last a long time if used correctly.

Another frequently asked question concerns safety. It is important to always use personal protective equipment, such as goggles and gloves, when working with abrasive brushes to protect yourself from flying debris.

Innovations in the field of abrasive brushes

In recent years, there have been significant innovations in the design and materials of abrasive brushes. These innovations have led to more efficient brushes that offer longer life and improved performance. For example, the use of advanced ceramic materials has made it possible to create brushes that can work at higher temperatures and with greater wear resistance.

Conclusion

Professional abrasive brushes are an essential component for machine shops and the manufacturing industry. They offer a versatile and efficient solution for a wide range of applications, helping to improve the quality and efficiency of production processes. With proper selection and use, abrasive brushes can be a valuable investment for any operator in the industry.

Read More Read LessUnderstanding Professional Abrasive Brushes

Abrasive brushes consist of a backing, usually metal or plastic, onto which abrasive bristles are attached. These bristles can be made of different materials, including silicon carbide, aluminium oxide or ceramic, depending on the specific application. The choice of abrasive material is crucial, as it determines the brush's ability to remove material and the finish it can achieve.

Applications of Abrasive Brushes

Abrasive brushes are used in numerous industrial applications. They are used for cleaning surfaces, removing burrs, preparing surfaces for painting, and finishing metal components. Their ability to adapt to uneven surfaces makes them particularly useful in contexts where precision is paramount.

Advantages of Professional Abrasive Brushes

One of the main advantages of abrasive brushes is their versatility. They can be used on a wide range of materials, including metals, wood and plastic. In addition, they offer precise control over the amount of material removed, reducing the risk of damage to the workpiece. Abrasive brushes are also known for their durability and resistance to wear, making them a worthwhile investment for machine shops.

Correct use of abrasive brushes

To achieve the best results, it is essential to use the abrasive brushes correctly. This includes choosing the right brush for the specific application, setting the appropriate rotation speed and applying the right pressure. Improper use can lead to unsatisfactory results and premature brush wear.

Frequently asked questions about abrasive brushes

One of the most common questions concerns the durability of abrasive brushes. Durability depends on several factors, including the material of the brush, the application and the conditions of use. In general, high-quality abrasive brushes can last a long time if used correctly.

Another frequently asked question concerns safety. It is important to always use personal protective equipment, such as goggles and gloves, when working with abrasive brushes to protect yourself from flying debris.

Innovations in the field of abrasive brushes

In recent years, there have been significant innovations in the design and materials of abrasive brushes. These innovations have led to more efficient brushes that offer longer life and improved performance. For example, the use of advanced ceramic materials has made it possible to create brushes that can work at higher temperatures and with greater wear resistance.

Conclusion

Professional abrasive brushes are an essential component for machine shops and the manufacturing industry. They offer a versatile and efficient solution for a wide range of applications, helping to improve the quality and efficiency of production processes. With proper selection and use, abrasive brushes can be a valuable investment for any operator in the industry.