Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Chemical, adhesives and sealants

- Home

- Chemical, adhesives and sealants

- Protections for maintenance

Protections for maintenance

Industrial maintenance protectants are a crucial element in ensuring the efficiency and longevity of equipment in machine shops. These products are designed to protect metal surfaces and mechanical components from wear, corrosion and other environmental factors that can compromise machine performance. In an industrial context, where equipment is subjected to constant stress, the importance of proper maintenance cannot be underestimated.

The importance of industrial maintenance protection

In the machine shop sector, equipment is the beating heart of daily operations. Their efficiency and reliability depend largely on the quality of the maintenance they undergo. Industrial maintenance protectants play a key role in this process, providing a protective barrier against external agents such as moisture, dust and chemicals. These products not only prevent corrosion and wear, but also help to reduce downtime, thereby improving overall productivity.

How industrial maintenance protectants work

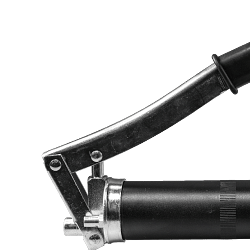

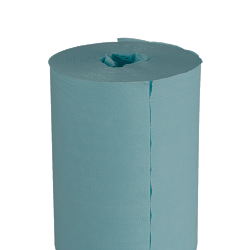

Industrial maintenance protectants are formulated to adhere firmly to metal surfaces, creating a protective layer that prevents direct contact with corrosive agents. These products can be applied as sprays, liquids or pastes, depending on the specific needs of the application. Once applied, they form a resistant film that protects surfaces from oxidation and mechanical wear. Some protectants also have lubricating properties, which reduce friction between moving parts, further prolonging equipment life.

Benefits of using industrial maintenance protectants

The adoption of industrial maintenance protectants offers several advantages. Firstly, they help reduce maintenance costs, as protected equipment requires less frequent and less costly servicing. They also improve operational safety, reducing the risk of sudden breakdowns that could lead to accidents at work. Another significant benefit is the increase in equipment life, which translates into a higher return on investment for companies. Finally, the use of protective covers helps maintain a cleaner and safer working environment by reducing the dispersion of dust and chemicals into the air.

Practical applications of protective covers for industrial maintenance

In machine shops, industrial maintenance protective covers find application in a wide range of situations. They can be used to protect heavy machinery, such as lathes and milling machines, as well as smaller equipment such as hand tools and precision components. They are also ideal for protecting surfaces exposed to adverse environmental conditions, such as high humidity or corrosive atmospheres. Regular application of protective coatings on these surfaces helps keep equipment in optimum condition, minimising wear and tear and prolonging its service life.

Frequently asked questions about industrial maintenance protection

1. What types of protective products are available on the market?

There are different types of industrial maintenance protectants, including protective sprays, lubricating oils, greases and protective pastes. Choosing the right product depends on the specific requirements of the application and the operating conditions.

2. How often should protectants be applied?

The frequency of application depends on the operating environment and the type of equipment. In general, it is advisable to apply protectants regularly, following the manufacturer's instructions, to ensure continuous protection.

3. Can protectants be used on all types of metal?

Most industrial maintenance protectants are formulated to be compatible with a wide range of metals, including steel, aluminium and copper. However, it is important to check the product specifications to ensure that it is suitable for the type of metal being protected.

4. What are the criteria for choosing a quality protector?

When choosing a protector, it is important to consider factors such as corrosion resistance, ease of application, material compatibility and specific operating conditions. Opting for products from reputable brands with good reviews can ensure effective and long-lasting protection.

5. Are industrial maintenance protectants environmentally friendly?

Many manufacturers are developing environmentally friendly protectors, formulated with ingredients that are less harmful to the environment. It is possible to find products that offer a good balance between effectiveness and environmental sustainability.

Conclusions

Industrial maintenance protectants are essential tools for ensuring the longevity and efficiency of equipment in machine shops. They offer effective protection against corrosion and wear, helping to reduce maintenance costs and improve operational safety. Choosing the right protectant and applying it regularly are key to maximising the benefits of these products. With proper maintenance, equipment can continue to function optimally, supporting the productivity and competitiveness of companies in the long term.

Read More Read LessThe importance of industrial maintenance protection

In the machine shop sector, equipment is the beating heart of daily operations. Their efficiency and reliability depend largely on the quality of the maintenance they undergo. Industrial maintenance protectants play a key role in this process, providing a protective barrier against external agents such as moisture, dust and chemicals. These products not only prevent corrosion and wear, but also help to reduce downtime, thereby improving overall productivity.

How industrial maintenance protectants work

Industrial maintenance protectants are formulated to adhere firmly to metal surfaces, creating a protective layer that prevents direct contact with corrosive agents. These products can be applied as sprays, liquids or pastes, depending on the specific needs of the application. Once applied, they form a resistant film that protects surfaces from oxidation and mechanical wear. Some protectants also have lubricating properties, which reduce friction between moving parts, further prolonging equipment life.

Benefits of using industrial maintenance protectants

The adoption of industrial maintenance protectants offers several advantages. Firstly, they help reduce maintenance costs, as protected equipment requires less frequent and less costly servicing. They also improve operational safety, reducing the risk of sudden breakdowns that could lead to accidents at work. Another significant benefit is the increase in equipment life, which translates into a higher return on investment for companies. Finally, the use of protective covers helps maintain a cleaner and safer working environment by reducing the dispersion of dust and chemicals into the air.

Practical applications of protective covers for industrial maintenance

In machine shops, industrial maintenance protective covers find application in a wide range of situations. They can be used to protect heavy machinery, such as lathes and milling machines, as well as smaller equipment such as hand tools and precision components. They are also ideal for protecting surfaces exposed to adverse environmental conditions, such as high humidity or corrosive atmospheres. Regular application of protective coatings on these surfaces helps keep equipment in optimum condition, minimising wear and tear and prolonging its service life.

Frequently asked questions about industrial maintenance protection

1. What types of protective products are available on the market?

There are different types of industrial maintenance protectants, including protective sprays, lubricating oils, greases and protective pastes. Choosing the right product depends on the specific requirements of the application and the operating conditions.

2. How often should protectants be applied?

The frequency of application depends on the operating environment and the type of equipment. In general, it is advisable to apply protectants regularly, following the manufacturer's instructions, to ensure continuous protection.

3. Can protectants be used on all types of metal?

Most industrial maintenance protectants are formulated to be compatible with a wide range of metals, including steel, aluminium and copper. However, it is important to check the product specifications to ensure that it is suitable for the type of metal being protected.

4. What are the criteria for choosing a quality protector?

When choosing a protector, it is important to consider factors such as corrosion resistance, ease of application, material compatibility and specific operating conditions. Opting for products from reputable brands with good reviews can ensure effective and long-lasting protection.

5. Are industrial maintenance protectants environmentally friendly?

Many manufacturers are developing environmentally friendly protectors, formulated with ingredients that are less harmful to the environment. It is possible to find products that offer a good balance between effectiveness and environmental sustainability.

Conclusions

Industrial maintenance protectants are essential tools for ensuring the longevity and efficiency of equipment in machine shops. They offer effective protection against corrosion and wear, helping to reduce maintenance costs and improve operational safety. Choosing the right protectant and applying it regularly are key to maximising the benefits of these products. With proper maintenance, equipment can continue to function optimally, supporting the productivity and competitiveness of companies in the long term.