< Lubricants for machine tools Oil separator

Metalworking fluid dispensers are an essential component of the modern machine shop landscape. These often underestimated devices play a crucial role in maintaining operational efficiency and reducing maintenance costs. In this in-depth look at what metalworking fluid oilers are, how they work, their benefits and answers to frequently asked questions.

Understanding metalworking fluids

Coolant/oil separators are devices designed to separate oil from metalworking fluids used in machine tools. These fluids are essential for cooling and lubrication during metal cutting and machining operations. However, over time, foreign oil can contaminate the metalworking fluid, compromising its effectiveness and reducing machine life.

How oil separators work

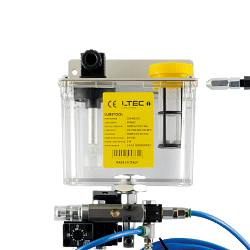

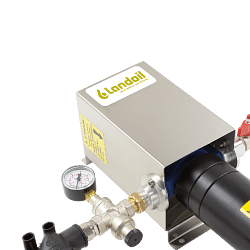

The operating principle of oil separators is based on the difference in density between the oil and the metalworking fluid. The oil, being less dense, tends to float on the surface of the fluid. Oil separators use various methods to collect and remove this oil, including rotating discs, belts or coalescence systems. Once separated, the oil is collected in a special container, allowing the clean metalworking fluid to be reused.

Advantages of using oil skimmers

The use of metalworking fluid deoiling offers several advantages. Firstly, it improves the quality of the metalworking fluid, extending its service life and reducing the frequency of replacement. This translates into significant cost savings for machine shops. In addition, the removal of foreign oil reduces wear and tear on machine tools, improving operational efficiency and decreasing downtime.

Environmental impact and sustainability

Another crucial aspect of oil skimmers is their contribution to environmental sustainability. By reducing the amount of contaminated metalworking fluids to be disposed of, the environmental impact of industrial operations is reduced. In addition, the recovered oil can be recycled or disposed of in a more environmentally friendly manner, contributing to more responsible resource management.

Frequently asked questions about metalworking fluid de-oilers

1. How often should I clean the oil skimmer?

The frequency of cleaning depends on the intensity of use and the type of metalworking fluid used. In general, regular maintenance is advisable to ensure optimal function.

2. Are oil separators suitable for all types of metalworking fluids?

Most oil separators are designed to work with a wide range of metalworking fluids. However, it is important to check compatibility with the manufacturer.

3. What is the average lifetime of a deoiler?

With proper maintenance, an oil separator can last several years. The exact service life depends on the model and operating conditions.

4. Can I install an oil skimmer on any machine tool?

Yes, oil/oil separators are generally compatible with most machine tools. However, specific adaptation may be necessary for certain applications.

5. What are the signs that an oil separator is needed?

If you notice an increase in the frequency of metalworking fluid changes or a decrease in machine performance, it may be time to consider installing an oiler.

Conclusions

Metalworking fluid oilers are indispensable tools for machine shops wishing to optimise their operations and reduce costs. In addition to the economic benefits, they contribute to a cleaner and more sustainable working environment. Investing in an oil skimmer not only improves operational efficiency, but is also a step towards more responsible and environmentally friendly industrial practices.

Read More Read Less