< Lubricants for machine tools Air coolers

Compressed air coolers for CNC are an essential component for modern machine shops, where precision and efficiency are paramount. These devices are designed to keep numerically controlled (CNC) machines at the optimum temperature, thus ensuring high performance and long equipment life. In this in-depth look, we will explore in detail what CNC air coolers are, how they work, their benefits and answers to frequently asked questions.

Understanding compressed air coolers for CNC

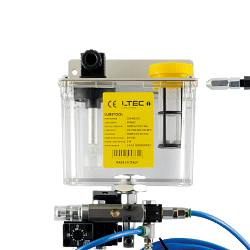

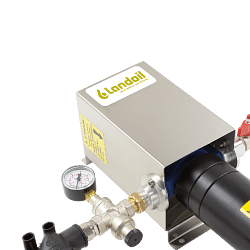

Compressed air coolers for CNC are devices that use compressed air to cool CNC machines. These systems are designed to dissipate heat generated during machine operation, preventing overheating and ensuring that equipment operates efficiently. The operating principle is based on the expansion of compressed air, which absorbs heat and dissipates it into the surrounding environment.

The importance of cooling in CNC machines

CNC machines are used for a wide range of applications, from milling to turning, and operate at high speeds. During operation, they generate a significant amount of heat, which can adversely affect machining performance and accuracy. Effective cooling is therefore crucial to maintain thermal stability and prevent deformation or damage to machine components.

Advantages of compressed air coolers for CNC

The adoption of compressed air coolers for CNCs offers numerous advantages. First of all, they improve the operational efficiency of machines, reducing downtime due to overheating. They also help to extend equipment life by reducing wear and tear on critical components. Another significant benefit is the reduction of energy costs, as compressed air coolers are generally more energy efficient than other cooling systems.

How to choose the right compressed air cooler

Choosing the right compressed air cooler for your workshop depends on several factors, including the technical specifications of your CNC machines, production volume and environmental conditions. It is important to consider the required cooling capacity, compatibility with existing equipment and the energy efficiency of the system. Furthermore, it is advisable to opt for models that offer ease of maintenance and reliable technical support.

Installation and maintenance of air coolers

The correct installation of compressed air coolers is essential to ensure their effectiveness. It is essential to follow the manufacturer's instructions and ensure that the system is correctly connected to the CNC machines. Regular maintenance is equally important to maintain optimum performance. This includes cleaning filters, checking connections and ensuring valves and internal components are working properly.

Answers to frequently asked questions

1. What is the difference between a compressed air cooler and a liquid cooling system?

Compressed air coolers use air to dissipate heat, whereas liquid cooling systems use refrigerants. Compressed air coolers are generally easier to install and maintain, but liquid cooling systems can offer greater cooling capacity in high-intensity applications.

2. How often is maintenance required on compressed air coolers?

The frequency of maintenance depends on usage and operating conditions. However, it is advisable to perform routine checks at least once a month to ensure that the system is working properly.

3. Are compressed air coolers suitable for all CNC machines?

Most compressed air coolers are compatible with a wide range of CNC machines, but it is important to check the manufacturer's specifications and recommendations to ensure that the system you choose is suitable for your needs.

4. What are the signs of a compressed air cooler malfunction?

Signs of a malfunction can include an increase in the operating temperature of the CNC machines, unusual noises coming from the cooling system or a reduction in cooling efficiency. If in doubt, it is advisable to contact a qualified technician for an evaluation.

5. Can the energy efficiency of compressed air coolers be improved?

Yes, energy efficiency can be improved through regular maintenance, the use of high-efficiency components and optimisation of operational settings. In addition, the adoption of advanced technologies, such as smart controls, can help reduce overall energy consumption.

In conclusion, compressed air coolers for CNC are an effective solution for ensuring the optimal operation of CNC machines. They offer numerous benefits, including increased operational efficiency, reduced energy costs and longer equipment life. Choosing the right system and maintaining it correctly is essential to maximise the benefits and ensure the continuity of operations in machine shops.

Read More Read Less