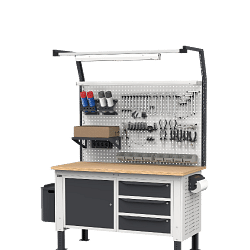

< Furnishings and storage Work benches

Professional workbenches: the beating heart of machine shops

In the world of mechanical workshops, professional workbenches are a key element in ensuring efficiency, precision and safety. These tools are not simply surfaces on which to work, but real operational centres that support technicians in the realisation of complex projects. The choice of the right workbench can significantly influence the productivity and quality of the work performed.

The importance of professional workbenches

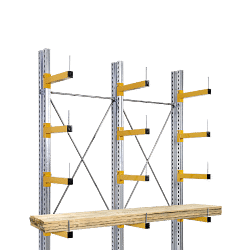

Professional workbenches are designed to withstand heavy loads and demanding working conditions. They are constructed of high-quality materials, such as stainless steel or strong metal alloys, to ensure durability and stability. Their robust construction is essential for supporting heavy equipment and withstanding daily wear and tear.

In addition to robustness, professional workbenches offer a range of features that make them indispensable in a mechanical working environment. These include drawers and compartments for organising tools, non-slip surfaces for safety, and height adjustment options to suit the ergonomic needs of operators.

Benefits of using professional workbenches

The adoption of professional workbenches in machine shops has several advantages. First of all, they improve operational efficiency. A well-organised bench allows technicians quick access to the necessary tools, reducing downtime and increasing productivity.

Secondly, they help improve the quality of work. The stability and robustness of the bench allows precision machining, reducing the risk of errors and defects in the finished products. Furthermore, the possibility of customising the bench with specific accessories allows it to be adapted to the particular needs of each project.

Finally, professional workbenches improve safety in the workplace. Non-slip surfaces and rounded edges reduce the risk of accidents, while the organisation of tools minimises clutter and prevents accidents caused by equipment left lying around.

How to choose the ideal professional workbench

Choosing the ideal professional workbench depends on several factors, including the type of work to be performed, the space available and the budget. It is important to consider the size of the bench, ensuring that it is large enough to accommodate all the necessary equipment, but also compact enough to fit into the available space.

Another crucial aspect is the bench's load capacity. It is essential to choose a model that can support the weight of the tools and materials used, avoiding deformation or structural damage. Furthermore, the presence of drawers and compartments for organising tools is an element that should not be underestimated, as it helps keep the work area tidy and functional.

Frequently asked questions about professional workbenches

1. What materials are best for professional workbenches?

The most common materials for professional workbenches are stainless steel and strong metal alloys. These materials offer a combination of strength, durability and corrosion resistance, making them ideal for demanding work environments.

2. Is it possible to customise a professional workbench?

Yes, many manufacturers offer customisation options for professional workbenches. Accessories such as drawers, compartments, electrical outlets and non-slip surfaces can be added to adapt the bench to the specific needs of the workshop.

3. How do you maintain a professional workbench in good condition?

Regular maintenance is essential to ensure the longevity of a professional workbench. It is important to regularly clean the surface, lubricate moving parts and check for signs of wear or damage. In addition, it is advisable to follow the manufacturer's instructions for maintenance specific to the model purchased.

Conclusion

Professional workbenches are an essential investment for any machine shop that wants to improve the efficiency, quality and safety of its working environment. Choosing the right workbench, customising it to your needs, and maintaining it in good condition are key steps to ensure successful day-to-day operations. With the right care and attention, a professional workbench can become the beating heart of a workshop, supporting technicians in the realisation of high quality projects and contributing to the achievement of company goals.

Read More Read Less