< Furnishings and storage Modular plinths

Modular modular platforms are an innovative and versatile solution in the context of machine shops and manufacturing industries. These flooring systems offer a number of advantages that make them indispensable for improving operational efficiency and ensuring a safe and organised working environment. In this in-depth look, we will explore in detail what modular mats are, how they are used, the benefits they offer, and answer some of the most frequently asked questions on this topic.

Introduction to modular footplates

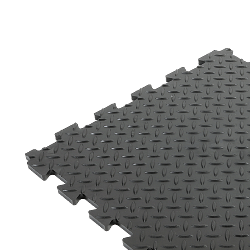

Modular modular decks are flooring structures designed to be easily assembled and customised to the specific needs of a work environment. Made of strong and durable materials, such as steel or polypropylene, these mats are designed to withstand heavy loads and withstand daily wear and tear. Their modularity allows for customised configurations, fitting perfectly into spaces of different sizes and shapes.

Use of modular mats in machine shops

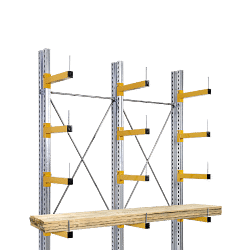

In machine shops, modular mats play a crucial role in improving work organisation and efficiency. They can be used to create safe and well-defined routes, separate specific work areas or elevate machinery and equipment for easy access and maintenance. The possibility of customising the configuration of the platforms makes it possible to optimise the available space, minimising clutter and improving movement within the workshop.

Advantages of modular running boards

One of the main advantages of modular platforms is their flexibility. Thanks to the possibility of adding or removing modules, it is possible to quickly adapt the floor configuration to changing operational needs. This translates into greater efficiency and productivity, as workshops can reorganise spaces without having to undertake costly and time-consuming renovation work.

In addition, modular platforms offer a high level of safety. Their non-slip surface reduces the risk of accidents at work, while their ability to withstand heavy loads ensures the stability of equipment placed on them. This is especially important in machine shops, where safety is a top priority.

Materials and design of modular platforms

Modular modular platforms are available in a variety of materials, each with specific characteristics that determine their suitability for different work environments. Steel, for example, is ideal for applications requiring exceptional strength and durability. Polypropylene, on the other hand, is lightweight and resistant to chemicals, making it suitable for environments where corrosion resistance is required.

The design of the modular platforms is designed for easy installation and maintenance. The modules are designed to fit perfectly together, creating a uniform and stable surface. In addition, many modular decking systems include accessories such as ramps and finishing edges, which further enhance the functionality and aesthetics of the decking.

Frequently asked questions about modular decking

1. How easy is it to install modular decks?

The installation of modular modular decks is generally quick and easy. Due to their modular design, the individual panels can be easily assembled without the need for special tools. This saves time and reduces installation costs.

2. Can modular modular decks be used outdoors?

Yes, many modular modular decks are designed to withstand outdoor weather conditions. However, it is important to choose the right material according to the specific environment in which they will be used. For example, polypropylene is water and UV-resistant, making it suitable for outdoor applications.

3. What is the load capacity of modular decks?

The load capacity of modular modular decks varies depending on the specific material and design. However, most systems are designed to withstand heavy loads, making them suitable for use in industrial environments and machine shops.

4. Is it possible to customise the colour of modular modular platforms?

Yes, many companies offer the possibility of customising the colour of modular modular decks to match the aesthetics of the work environment or to improve visibility and safety.

5. Do modular modular platforms require maintenance?

Modular modular decks require minimal maintenance. It is advisable to clean them regularly to remove dust and debris, but thanks to their strength and durability, they do not require frequent maintenance.

Conclusion

Modular modular platforms are an effective and versatile solution for improving organisation and safety in machine shops and industrial environments. Thanks to their flexibility, resistance and ease of installation, these platforms offer significant added value, helping to optimise space and ensure a safer and more efficient working environment. Choosing the right modular platforms can make all the difference in improving day-to-day operations and ensuring the long-term success of a company.

Read More Read Less