Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Furnishings and storage

- Home

- Furnishings and storage

- Containers for small metal parts

Containers for small metal parts

Industrial small parts containers: an essential element for machine shop efficiency

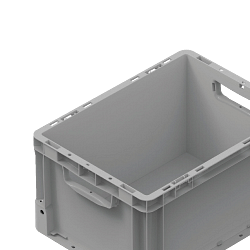

In the world of machine shops, organisation and efficiency are essential to ensure a smooth and productive workflow. Among the tools that help achieve these goals, industrial small parts containers play a crucial role. These containers, designed specifically for the management and storage of small parts, offer a practical and versatile solution for maintaining order and optimising work space.

The importance of industrial small parts containers

Industrial small parts containers are designed to hold and organise a wide range of small components, such as screws, bolts, washers and other fasteners. Their importance lies in their ability to improve operational efficiency by reducing the time needed to find and access necessary components during assembly or maintenance operations. In an environment where time is money, the ability to quickly access the right components can make the difference between a project being completed on time and one being delayed.

Distinctive features of industrial small parts containers

Industrial small parts containers come in a variety of shapes, sizes and materials, each designed to meet specific needs. Distinctive features include resistance to heavy loads, durability and the ability to withstand harsh environmental conditions, such as humidity and temperature variations. In addition, many of these containers are stackable, making it possible to optimise vertical space and facilitate access to stored components.

Materials and design: a strategic choice

The choice of material and design of industrial small parts containers is a strategic decision that can significantly influence operational efficiency. Common materials include durable plastic, metal and polypropylene, each with specific advantages. Plastic is lightweight and corrosion-resistant, while metal offers greater structural strength. Polypropylene, on the other hand, combines light weight and chemical resistance, making it ideal for industrial environments.

Advantages of using industrial small parts containers

The adoption of industrial small parts containers offers numerous advantages, including:

1. Improved organisation: The containers allow components to be classified and separated according to size, type or frequency of use, facilitating access and reducing the risk of errors.

2. Operational efficiency: With easily accessible components, time spent searching for specific parts is reduced, increasing overall productivity.

3. Waste reduction: Effective organisation reduces the risk of lost or damaged components, helping to reduce waste and associated costs.

4. Improved safety: Maintaining an orderly work area reduces the risk of accidents, improving the overall safety of the working environment.

5. Flexibility and scalability: Containers can be easily reorganised or expanded to accommodate changes in operational needs or inventory.

Frequently asked questions about industrial small parts containers

1. What are the criteria for choosing the right container?

Choosing the right container depends on various factors, including the type of parts to be stored, the space available and the environmental conditions of the workshop. It is also important to consider the frequency of use of the components and the need for quick access.

2. How are industrial small parts containers maintained?

Container maintenance is generally simple and consists of regular cleaning to remove dust and debris. It is important to periodically inspect the containers for damage or signs of wear that could affect their functionality.

3. Can containers be customised for specific needs?

Many manufacturers offer customisation options, such as adjustable internal dividers or labels for better component identification. These customisations can further improve efficiency and organisation.

Conclusion: a strategic investment for machine shops

In conclusion, industrial small parts containers are a strategic investment for machine shops wishing to improve operational efficiency and organisation. Their ability to optimise space, reduce search times and improve safety makes them an essential element of any industrial work environment. Choosing the right containers, keeping them in good condition and adapting them to specific needs can lead to significant improvements in productivity and resource management.

Read More Read LessIn the world of machine shops, organisation and efficiency are essential to ensure a smooth and productive workflow. Among the tools that help achieve these goals, industrial small parts containers play a crucial role. These containers, designed specifically for the management and storage of small parts, offer a practical and versatile solution for maintaining order and optimising work space.

The importance of industrial small parts containers

Industrial small parts containers are designed to hold and organise a wide range of small components, such as screws, bolts, washers and other fasteners. Their importance lies in their ability to improve operational efficiency by reducing the time needed to find and access necessary components during assembly or maintenance operations. In an environment where time is money, the ability to quickly access the right components can make the difference between a project being completed on time and one being delayed.

Distinctive features of industrial small parts containers

Industrial small parts containers come in a variety of shapes, sizes and materials, each designed to meet specific needs. Distinctive features include resistance to heavy loads, durability and the ability to withstand harsh environmental conditions, such as humidity and temperature variations. In addition, many of these containers are stackable, making it possible to optimise vertical space and facilitate access to stored components.

Materials and design: a strategic choice

The choice of material and design of industrial small parts containers is a strategic decision that can significantly influence operational efficiency. Common materials include durable plastic, metal and polypropylene, each with specific advantages. Plastic is lightweight and corrosion-resistant, while metal offers greater structural strength. Polypropylene, on the other hand, combines light weight and chemical resistance, making it ideal for industrial environments.

Advantages of using industrial small parts containers

The adoption of industrial small parts containers offers numerous advantages, including:

1. Improved organisation: The containers allow components to be classified and separated according to size, type or frequency of use, facilitating access and reducing the risk of errors.

2. Operational efficiency: With easily accessible components, time spent searching for specific parts is reduced, increasing overall productivity.

3. Waste reduction: Effective organisation reduces the risk of lost or damaged components, helping to reduce waste and associated costs.

4. Improved safety: Maintaining an orderly work area reduces the risk of accidents, improving the overall safety of the working environment.

5. Flexibility and scalability: Containers can be easily reorganised or expanded to accommodate changes in operational needs or inventory.

Frequently asked questions about industrial small parts containers

1. What are the criteria for choosing the right container?

Choosing the right container depends on various factors, including the type of parts to be stored, the space available and the environmental conditions of the workshop. It is also important to consider the frequency of use of the components and the need for quick access.

2. How are industrial small parts containers maintained?

Container maintenance is generally simple and consists of regular cleaning to remove dust and debris. It is important to periodically inspect the containers for damage or signs of wear that could affect their functionality.

3. Can containers be customised for specific needs?

Many manufacturers offer customisation options, such as adjustable internal dividers or labels for better component identification. These customisations can further improve efficiency and organisation.

Conclusion: a strategic investment for machine shops

In conclusion, industrial small parts containers are a strategic investment for machine shops wishing to improve operational efficiency and organisation. Their ability to optimise space, reduce search times and improve safety makes them an essential element of any industrial work environment. Choosing the right containers, keeping them in good condition and adapting them to specific needs can lead to significant improvements in productivity and resource management.